Since 2001, EN 166:2001 has been used for CE and UKCA certification of safety eyewear in the European Union and United Kingdom. It is now being replaced by EN ISO 16321 – a new set of international standards that will bring some significant changes to product requirements and test methods. This guide provides the key information you need to know about the new ISO standard to ensure you can remain compliant and provide effective eye protection to keep your workplace safe.

Introducing the new ISO standard

When does it come into force?

EN ISO 16321 was officially published as the replacement for EN 166 in May 2023. The legal adoption date is 11th November 2025 and only products that meet its standards may be tested and certified by official bodies from this date onwards. However, existing EN 166 certificates which are often used for CE/UKCA markings, will remain valid until their official expiry date up to a maximum of five years. This means, for example, that any products certified or recertified according to EN 166 by 11th November 2025 can be sold legally by manufacturers until 31 October 2029. There is no end date for distributors to have sold their EN certified products by.

Where will it apply?

The new ISO standard will become the official standard in many of the world’s leading PPE markets including the European Union and the UK. Others – such as Russia – will retain the EN standard at this stage.

Why is the standard changing?

ISO can be adopted worldwide and allows for global harmonisation of safety requirements. This is set to lead to greater consistency across international product markings over the course of the coming decade and help to ensure universal minimum standards.

Overview of the key changes

EN ISO 16321 comprises EN ISO 16321-1:2022, EN ISO 16321-2:2021 and EN ISO 16321- 3:2022. It introduces numerous changes from EN 166 regarding safety features and testing requirements. It will involve new certificates and changes in labelling, markings, instructions and packaging for all safety eyewear. The ISO standard includes new safety requirements and new optional features. In some cases, the new standard demands a higher level of protection. In others, the standards become less stringent. The most significant changes are outlined in greater detail in the following:

EN Standard

EN 170 Ultraviolet filters

EN 171 Infrared filters

EN 172 Solar radiation filters

ISO Standard

EN ISO 16321-1:2022 Eye and face protection for

occupational use - Part 1:

General requirements

EN ISO 16321-1:2022 Part 6.3.1

EN ISO 16321-1:2022 Part 6.3.2

EN ISO 16321-1:2022 Part 6.3.3

Summary

EN ISO 16321 and related parts only applies to plano and prescription glasses for occupational use or use in educational establishments. It excludes face protectors intended for live-working to protect against short-circuit electric arcs, laser protectors, sports eyewear, protectors for use during medical applications, protectors for medically prescribed applications; protectors specifically intended for protection against solar radiation only or protectors intended to protect against ionizing radiation.

EN Standard

EN 169 Filters for welding and related techniques.

ISO Standard

EN ISO 16321-2:2021 Eye and face protection for occupational use — Part 2: Additional requirements for protectors used during welding and related techniques.

Summary

The new EN ISO 16321-2 standard is broader than EN169 as it applies to complete eye and face protectors used in welding and similar techniques. It includes additional considerations such as frame design and materials suitable for withstanding welding heat and sparks-compatibility with respiratory equipment.

EN Standard

EN 1731 Mesh type eye and face protectors for industrial and non-industrial use against mechanical hazards and heat.

ISO Standard

EN ISO 16321-3:2022 Eye and face protection for occupational use — Part 3: Additional requirements for mesh protectors

Summary

Used alongside EN ISO 16321-3:2022, this standard defines the requirements for mesh eye and face protectors which protect against mechanical hazards like flying particles and debris. Notably, a key difference from the older EN 1731:2006 standard lies in the mesh design, particularly the aperture count.

EN Standard

EN 167 Personal eye protection - optical test methods

ISO Standard

EN ISO 18526-1:2020 Eye and face protection - Test methods Part 1: Geometrical optical properties

Summary

The EN 167 standard focuses on optical testing methods for eye protection lenses whereas the EN ISO 18526-1:2020 is a broader standard focusing on geometrical optical testing methods for a wider range of eye and face protection.

EN Standard

EN 170 Ultraviolet filters

EN 171 Infrared filters

EN 172 Solar radiation filters

ISO Standard

EN ISO 18526-2:2020 Eye and face protection — Test methods — Part 2: Physical optical properties (Filters)

Summary

The new ISO 18526-2:2020 standard provides a single source of information for testing all types of filters. It uses more advanced testing methods and promotes consistency across different types of eye and face protection.

EN Standard

EN 168 Personal eye protection - non-optical test methods

ISO Standard

EN ISO 18526-3:2020 Eye and face protection — Test

methods — Part 3: Physical and mechanical properties

Summary

The new ISO standard covers more test methods for both eye and face protection building upon EN168 with a wider range of tests including specific hazards like splashes of molten metals, chemicals, or hot liquids. It also covers the complete eye protector and not just the lens.

ISO Standard

EN ISO 18526-4:2020 Eye and face protection — Test methods — Part 4: Headforms

Summary

Tests eyewear on six different head and facial sizes intended to replicate 95% of the world’s population.

Safety requirements

Headforms

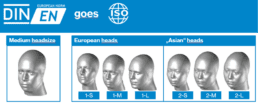

The biggest change in the new ISO standard concerns headforms. Head shapes and sizes can differ significantly from person to person. EN 166 specified only medium and small headforms, with the vast majority of testing carried out on the medium size. This approach all too frequently led to a one-size-fits-all approach to safety eyewear that compromised workers’ comfort and their equipment’s performance.

ISO 16321 covers six different options which, following extensive international research, represents around 95% of head shapes and sizes of the world’s population. Manufacturers must carry out tests based on the fit and coverage area of the specific headform. If a product is certified only to size M no marking is required on the product. However, if a product fits multiple headsizes the marking denoting this can be found on the product and/or on the product’s packaging.

| Small | Medium | Large | |

| European heads | 1-S | 1-M | 1-L |

| Asian heads | 2-S | 2-M | 3-L |

At uvex, we have always made it a priority to provide PPE that fits. We already run a highly successful eyewear fit programme that considers the employee’s facial features, work environment and personal requirements, including compatibility with other PPE. Our current range includes a broad array of options to suit different headforms and we are planning to secure multiple certifications in line with the ISO 16321 standard. This will include premium adjustable models with innovative features to ensure the ultimate close fit as well as models that are available in different sizes.

Mechanical strength

Mechanical strength, otherwise known as the impact strength, is crucial in safety eyewear to protect the eyes from potential injuries caused by flying debris, projectiles or other impacts in hazardous work environments. A “bullet test” is carried out to determine the mechanical impact resistance against projectiles based on their speed, as measured in metres per second.

In the old EN166:2001 standard there were different levels of impact resistance ranging from increased robustness in the drop ball test (level S), low energy impact resistance (level F), medium energy impact resistance applicable for goggles (level B) and high energy impact (level A) used only for face shields.

The new standards introduce three new impact levels (C, D, and E) alongside revised velocity speeds. As outlined in the table below, the EN ISO 16321 tests for a lower speed of impact for safety goggles and face guards than the EN standard, yet the diameter and weight of the steel ball used for the measurements has increased.

EN 166:2001 Steel ball measurements

- 22 mm Diameter

- 43 Grams

EN ISO 16321-1 Steel ball measurements

- 25 mm Diameter

- 66 Grams

The ISO standard also introduces a requirement for “protection zones”, with their sizes determined by the potential speed of the projectiles in the workplace. Eyewear under impact level C must include an orbital protection zone (OPZ), eyewear under impact level D must include an extended orbital protection zone (EOZ), and eyewear under impact level E must include a face protection zone (FPZ). These “protection zones” outline minimum areas of coverage to protect the wearer. The higher the speed of impact, the larger the protection zone coverage.

Eye protection

Old EN166 / 168

Impact resistance level and velocity

S

Dropball test

New ISO 16321-1

Impact resistance level and velocity

Dropball test

(no marking)

New ISO 16321-1

Protection Zone

–

Old EN166 / 168

Impact resistance level and velocity

F

45 m/s

New ISO 16321-1

Impact resistance level and velocity

C

45 m/s

New ISO 16321-1

Protection Zone

Orbital Protection Zone (OPZ)

Old EN166 / 168

Impact resistance level and velocity

B

120 m/s

New ISO 16321-1

Impact resistance level and velocity

D

80 m/s

New ISO 16321-1

Protection Zone

Extendend Orbital Protection Zone (EOZ)

Face guard

Old EN166 / 168

Impact resistance level and velocity

A

190 m/s

New ISO 16321-1

Impact resistance level and velocity

E

120 m/s

New ISO 16321-1

Protection Zone

Face Protection Zone (FPZ)

m/s = meters per second

This reduced requirement reflects the global harmonisation of the standard, with EN 166 having offered a uniquely high level of testing. At uvex, we have our own in-house standards known as the uvex house norms. To guarantee the high quality and integrity of our products we exceed industry regulations with our own rigorous tests that go beyond the standard requirements. As a result, uvex will continue to test products to the higher speeds of the European impact standard EN 166:2001. While products under impact level D (80m/s) will be marked as such, our products will still conform to the EN166 B (120 m/s) test.

Lens filters

Integrated filters in the lens must fulfil a range of requirements to protect the eyes from the various dangers of optical radiation. They may also require additional features, such as the ability to accurately transmit and differentiate colours as required for specific signalling or warning systems.

The protective features under the new ISO standard remain largely the same as under EN 166, but the markings will change.

Ultraviolet protective filters

UV filters are designed to protect the eyes from harmful UV radiation. UV radiation can come from the sun (UVB and UVA radiation) as well as from artificial light sources such as (UVC, UVB and UVA radiation).

UV lens filter marking according to old EN 166/EN170

2-1,2

UV lens filter marking according to new EN ISO 16321-1:2022

U1,2

Meaning in terms of light transmittance

>=74.4% of the visible light is transmitted

UV lens filter marking according to old EN 166/EN170

2-1,4

UV lens filter marking according to new EN ISO 16321-1:2022

U1,4

Meaning in terms of light transmittance

Between <74.4% and >=58.1% of the visible light is transmitted

UV lens filter marking according to old EN 166/EN170

2-1,7

UV lens filter marking according to new EN ISO 16321-1:2022

U1,7

Meaning in terms of light transmittance

Between <58.1% and >=43.2% of the visible light is transmitted

UV lens filter marking according to old EN 166/EN170

2-2

UV lens filter marking according to new EN ISO 16321-1:2022

U2

Meaning in terms of light transmittance

Between <43.2% and >=29.1% of the visible light is transmitted

UV lens filter marking according to old EN 166/EN170

2-2,5

UV lens filter marking according to new EN ISO 16321-1:2022

U2,5

Meaning in terms of light transmittance

Between <29.1% and >=17.8% of the visible light is transmitted

UV lens filter marking according to old EN 166/EN170

2-3,1

UV lens filter marking according to new EN ISO 16321-1:2022

U3

Meaning in terms of light transmittance

Between <17.9% and >8.5% of the visible light is transmitted

UV lens filter marking according to old EN 166/EN170

2-4

UV lens filter marking according to new EN ISO 16321-1:2022

U4

Meaning in terms of light transmittance

Between <8.5% and >=3.2% of the visible light is transmitted

UV lens filter marking according to old EN 166/EN170

2-5

UV lens filter marking according to new EN ISO 16321-1:2022

U5

Meaning in terms of light transmittance

Between <3.2% and >=1.2% of the visible light is transmitted

Signal recognition remains an optional test under the EN ISO 16321:1:2022 (as it did under EN170) however, it is depicted by the L marketing – if it meets the standard, instead of the previous C.

Sunglare filters for occupational use

Sun protection filters are mainly intended to protect the eye from natural glare and the sun’s natural UV radiation (UVB and UVA radiation).

Sunglare protection filter marking according to the old EN 166/EN 172

5-1,1

Sunglare protection filter marking according to the new EN ISO 16321- 1:2022

G0

Meaning in terms of light transmittance

>=80% of the visible light is transmitted

Sunglare protection filter marking according to the old EN 166/EN 172

5-1,4

5-1,7

Sunglare protection filter marking according to the new EN ISO 16321- 1:2022

G1

Meaning in terms of light transmittance

Between <80% and >=43% of the visible light is transmitted

Sunglare protection filter marking according to the old EN 166/EN 172

5-2

5-2,5

Sunglare protection filter marking according to the new EN ISO 16321- 1:2022

G2

Meaning in terms of light transmittance

Between <43% and >=18% of the visible light is transmitted

Sunglare protection filter marking according to the old EN 166/EN 172

5-3,1

Sunglare protection filter marking according to the new EN ISO 16321- 1:2022

G3

Meaning in terms of light transmittance

Between <18% and >=8% of the visible light is transmitted

Sunglare protection filter marking according to the old EN 166/EN 172

5-4,1

Sunglare protection filter marking according to the new EN ISO 16321- 1:2022

G4

Meaning in terms of light transmittance

Between <8% and >=3% of the visible light is transmitted

Signal colour recognition was mandatory under EN172 however, this is now an optional test under EN ISO 16321-1:2022 and depicted with the L marking.

Infrared protective filters

Infrared filters are designed to protect the eyes from heat radiation, such as that emitted by molten glass or metal, fire, and artificial heat emitters. The protection level increases with the average temperature of the heat source. The new ISO standard introduces the option for enhanced infrared reflection, which is marked with an additional R.

Infrared protection, filter marking

| according to the old EN 166/EN 171 | according to the new EN ISO 16321:1:2022 |

| 4-1,2 | R1,2 |

| 4-1,4 | R1,4 |

| 4-1,7 | R1,7 |

| 4-2 | R2 |

| 4-2,5 | R2,5 |

| 4-3 | R3 |

| 4-4 | R4 |

| 4-5 | R5 |

| 4-6 | R6 |

| 4-7 | R7 |

| 4-8 | R8 |

| 4-9 | R9 |

| 4-10 | R10 |

| Amended criteria: now 1 requirement for the whole area 780-3000 nm |

|

| 4C + filter: compliant for signalling lights (colour recognition) | RL + filter: compliant for signalling lights (colour recognition) |

| – | RR + filter (with increased IR reflection) |

| – | RRL + filter (with colour recognition and increased IR reflection) |

Signal recognition remains an optional test under the EN ISO 16321:1:2022 (as it did under EN171) however, it is depicted by an L if it meets the standard (instead of a C).

Welding filters

The heat and intense brightness created during welding would cause irreparable damage to the eyes without proper protection.

Compliance for signalling lights was not part of the tests under the EN standard but this has been introduced under EN ISO 16321-2:2022 as an optional test and is depicted with the L marking. This means that signal colours remain unaffected by the lens shade.

Welding lens filter marking

| according to the old EN 166/EN 169 | according to the new EN ISO 16321:2:2022 |

| 1,2 | W1,2 |

| 1,4 | W1,4 |

| 1,7 | W1,7 |

| 2 | W2 |

| 2,5 | W2,5 |

| 3 | W3 |

| 4 | W4 |

| 5 | W5 |

| 6 | B6 |

| 7 | W7 |

| 8 | W8 |

| 9 | W9 |

| 10 | B10 |

| Compliance for signalling lights (colour recognition) was not part of the tests | WL + filter: compliant for signalling lights (colour recognition) |

Optional features

Further markings can be included on eye and face protection where additional safety features are included and meet the testing requirements set out in the ISO standard.

Summary of optional requirements include:

| Resistance against fogging | High mass impact NEW |

| Resistance to surface damage by fine particles | Protection against radiant heat NEW |

| Protection against gases and fine dust particles | Protection against streams of liquid NEW |

| Protection against large dust particles | Lens assessment for anti-reflective coatings NEW |

| Protection against molten metals and hot solids | Use in explosive atmospheres NEW |

| Chemical resistance NEW |

Under both the EN and EN ISO standards, several optional features and markings remain the same, albeit with slight modifications to some test procedures. The updates in these tests aim to harmonise standards and provide more concrete procedures for manufacturers and test laboratories. These include:

Marking: K

Feature: Protection against molten metals and hot solids

Description: Plastic is a very impact-resistant lens material but is also very soft and susceptible to scratches. For this reason, almost all safety spectacles are provided with an additional coating that can fulfil different tasks. In this optional test, sand trickles onto the lens and the degree of scratching is then measured in haze percentage. If the haze remains below 8%, the eye protection device qualifies for the marking. Lenses coated with uvex supravision sapphire are extremely scratch resistant on both sides whereas lenses coated with supravision excellence or supravision extreme are scratch resistant on the more dirt-prone outside of the lens and fog-free on the inside of the lens which is prone to fog-up due to sweat etc.

Marking: N

Feature: Resistance against fogging

Description:Fogged-up glasses pose a safety risk. This test requires lenses to remain fog-free for a minimum of eight seconds when exposed to an atmosphere above 50°C. However, simple anti-fog coatings wash out relatively quickly and become ineffective. For this reason, the lenses are placed in water for 2 hours before the anti-fog test to simulate this premature washing out. Lenses coated with uvex supravision excellence are anti-fog for at least 16 seconds and the coating is permanent and will not wash off even after repeated cleaning. uvex supravision plus coatings provide permanent antifog for at least 30 seconds. With uvex supravision extreme or supravision ETC fogging is not possible as the coating does not become saturated.

Marking: 3

Feature: Protection against droplets

Description:Under EN 166, goggles were tested by spraying liquids on frontally. Visors were measured to determine whether the surface was large enough to cover the face, with no liquid testing required. However, under EN ISO 16321-1:2022, the testing method has changed, with the droplets projected onto the visor in all directions.

Marking: 4

Feature: Protection against large dust particles

Description:For extremely dusty activities, very tight-fitting safety eyewear or even fullvision goggles are required.

Marking: 5

Feature: Protection against gases and fine dust particles

Description: Goggles with this marking are often referred to as gas-tight full-vision goggles or full-vision goggles without ventilation.

Marking: T

Feature: Mechanical strength at extreme temperatures

Description: Materials can behave very differently at extreme temperatures. To ensure sufficient mechanical protection at such temperatures, impact tests can also be carried out with products that have previously been preconditioned to +55°C and -5°C. While this feature was available under the EN standard, the tests now cover four impact levels: C (45m/s), D (80m/s), E (120m/s) and high mass.

Some markings have seen slight changes under the ISO standard with regard to range of eligible products. These include:

Marking: 9

Feature: Protection against molten metals and hot solids

Description: This test examines the non-adhesion and rapid penetration of hot, liquid metals on the lens and frame, as can occur when working in the metal industry. This marking no longer applies to goggles as molten metal presents a risk to the entire face. uvex stopped producing goggles in 2021 with the 9 marking for this exact reason.

EN ISO 16321-1:2022 also introduces a range of features that did not appear under EN 166. Some of the new developments are featured below:

Marking: HM

Feature: High mass impact

Description: This means mechanical protection against larger objects is tested at a reduced speed. This is adopted from the American standard for safety spectacles. uvex already carries out high mass impact testing in accordance with the ISO requirements and will mark products accordingly.

Marking: CH

Feature: Chemical resistance

Description: Unlike hand protection, there has not yet been an eyewear test procedure that confirms safe use when handling chemicals. The new ISO test involves pouring 100ml of sulphuric acid (30%), sodium hydroxide (10%), P-xylene, 1- Butanol and N-heptane over the full shield including the assembly system in 10 seconds and then leaving for five minutes. Visible deformation of the protector is not permitted, the image must not be distorted, and the assembly system must still work. Impact is also tested, as is resistance to ignition.

Marking: 6

Feature: Protection against streams of liquids

Description: This marking demonstrates that the protector prevents a high-pressure liquid stream from reaching the eyes of the wearer. Under ISO, this marking can be applied to goggles and visors.

Marking: 7

Feature: Protection against radiant heat

Description: This test is intended to determine whether the protector will protect the wearer’s face from radiant heat for a specified time. It only applies to a shield with a headband or helmet with an IR filter. The test is based on studies of typical fire conditions and any damage indicates that it may not protect the wearer’s eyes from the radiant heat.

Feature: Use in explosive atmospheres

Description: For protectors that are intended to be used in explosive atmospheres, and if the principal ignition source is electrostatic, the eyewear is tested according to ISO 80079- 36:2016, Annex D.

These advancements offer users more specific information about the safety eyewear required for specialised environments.

uvex - your benchmark for safety

We know that changes to standards can be a challenge. With the introduction of the EN ISO 16321 standard, safety professionals now have to cope with a number of new requirements.

But don’t worry: if you buy your safety spectacles from uvex, you are already a decisive step ahead, because: Not only do we fulfil all legally required standards, we produce products that even exceed them!

Our team will help you select the right products for your workplace. Simply get in touch with us using our contact form!