Implications of poorly fitted safety footwear on workers’ foot health and safety.

Foot pain and discomfort is extremely common in workers that are required to wear safety footwear. In a study of 358 miners 55% of the workers reported foot problems with 57% of the problems attributed to their safety footwear.1 Workers wearing incorrectly fitted safety footwear is one of the primary reasons for the unacceptable high levels of discomfort in workers, that is three times the level experienced in the general population.2

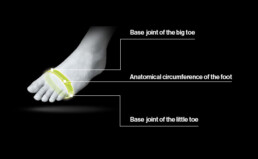

When comparing the three-dimensional scans of workers feet to their safety footwear, the majority of workers wear safety footwear that is 1-2 sizes too long in an attempt to get the required width.3 The alignment between workers foot shape and the protective elements of safety footwear is also notoriously poor for the protective elements of safety footwear including the toecap, heel, and arch region.4

Foot shapes vary enormously within the population with significant ratio differences in length, width and arch height of the foot. Adding to this variation is that foot shape is also dynamic and changes in shape throughout the walking cycle. Within each step the arch of the foot changes in height by 33% with corresponding changes in both foot length and width.5 The changes in foot shape during the walking cycle also vary significantly between individuals. It is the variations in foot shape and the dynamic changes throughout the walking cycle that makes the correct fitting of safety footwear so important.

Safety footwear that is too small can cause serious foot problems. Tight footwear can cause nerve entrapments within the foot resulting in pain, discomfort, and numbness. Prolonged wear of footwear that is too narrow can also cause damage to the intermetatarsal nerves and the development of a relatively common fibrous benign tumour called a Morton’s Neuroma. Morton’s Neuromas are characterised by sharp shooting, burning and radiating pain. The pain often begins intermittently but then becomes constant as the condition worsens. Morton’s Neuroma often require surgical removal to alleviate symptoms if conservative treatment fails.

Tight footwear is also more likely to cause rubbing, and blistering. While for most healthy people a blister is uncomfortable at the time, it will typically heal with no long-term effects. However, for people with diabetes or restricted blood supply to the feet a blister from footwear is the primary cause of ulceration and leg amputation. With 1 in 20 Australians suffering from diabetes6, correctly fitted safety footwear for these workers could be the difference between them losing their leg or being able to walk and maintain their mobility.

A common complication of diabetes is a condition called peripheral neuropathy which results in a loss of sensation and pain perception. The absence of sensation means that these people are unable to feel if the footwear fits correctly or if a blister is developing which can then lead to an ulceration and potential amputation. For workers with peripheral neuropathy it is critical that their safety footwear is fitted correctly to minimise the risks of serious health complications such as ulceration and amputation. Thankfully, the majority of healthy workers will immediately sense if the safety footwear is fitted too tight at the time of trying on the footwear.

Wearing safety footwear that is too large can also create complications. The majority of workers actually wear safety footwear that is too long in order to get the required width,3 making it more common to wear safety footwear too large, than too tight. Footwear that is too long creates a trip hazard due to the increased length of the footwear reducing ground clearance during the swing phase. With slips and trips being the second highest cause of serious claims in Australia, minimising trips through correctly fitting safety footwear is critical. Wearing safety footwear that is too large also reduces the amount of the foot that is protected by the safety toecap leaving more of the foot exposed to a crush injury.

Footwear is designed to flex and move with the foot and these functional areas are based on the footwear being correctly fitted. Footwear that is fitted too long shifts the ball of the joint, which goes through 60° of motion while walking, into a region of the footwear that is designed to be stiff and typically supported with a shank. This then inhibits the natural rollover and propulsive function of the foot and increases the workload of the calf muscles. The non-alignment between the ball of the foot and the flex point increases the torque at the ankle joint and consequently the fatigue development in the calf muscles over the workday. With lower limb fatigue present in 68% of automotive manufacturing workers7 and fatigue costing the USA economy $101 billion in lost productivity each year8, every effort should be made to reduce worker fatigue.

Footwear that is fitted too loose can also increase the risk of blistering due to the lack of lockdown in the footwear and the increased movement within the footwear. This is particularly important for the 1 in 5 Australians with diabetes and those with compromised blood supply due to the potential ulceration risks.

uvex Fitting Solutions

uvex has developed solutions to the significant health and workplace complications that can occur by wearing incorrectly fitted safety footwear. The uvex range of safety footwear has been developed with fitting profile based on the 3D scan data of Australian workers. The uvex multiplefit system provides two fitting widths in the majority of sizes to ensure the correct width can be obtained for a given foot length without having to go up in length.

How to fit work boots

Safety footwear is more difficult to fit than regular footwear due to the rigid safety toecap and the inability to check the foot position within the safety footwear.

The uvex multiplefit system has been developed to match the length and width of workers feet to the correct uvex safety footwear size and width. Workers feet can either be measured manually using a tape measure and the corresponding sizing table or electronically with the uvex fit advisor app. Different sized left and right feet for an individual is common and if this occurs the larger foot should be fitted. The consequences of wearing safety footwear slightly too tight are worse than those of wearing footwear slightly too big.

Ideally, footwear should be measured and fitted at the end of the day. During prolonged standing over a workday the foot and lower limb can undergo significant swelling due to the pooling of fluid even in healthy people. However, this is particularly important with workers that are slightly older and are more likely to have compromised lower limb circulation.

The socks worn during a typical workday should also be worn when fitting safety footwear to get a more accurate indication of the size requirements.

Safety Footwear Fitting Checklist

- Measure and fit footwear at the end of the day

- Wear socks that are worn during a typical workday.

- Length check: The longest toe should be a minimum of 10mm from the end of the insole to allow for the expansion of the foot while walking. The longest toe is often the second toe.

- Flex point: The ball of the foot should be positioned over the flex grooves so that the foot and footwear flex together.

- Width: The foot should sit entirely on the midsole and there should be no tension in the upper on top of the foot. This is to allow for the expansion of the foot during the loading phase while walking. The facing gap of the laces should be 30-40mm to allow for the footwear to be adjusted correctly if the upper material stretches during the wearing in period.

- Shaft volume: Facing gap between the shoelace eyelets around the ankle should be approximately 30-40mm when laced. This gap allows the footwear to be adjusted if ankle swelling occurs and or the upper material stretches during the wearing in period.

Contact us to talk to a uvex footwear specialist.

By Dr Caleb Wegener PhD (Biomechanics), B App Sc (Pod) Hons

uvex Director of Product Management // Honorary Research Associate, Faculty of Health Science, The University of Sydney

References

- Dobson et al., (2018). Are underground coal miners satisfied with their work boots? Applied Ergonomics. 66, 98-104.

- Hill et al., (2008). Prevalence and correlates of foot pain in a population-based study: The North West Adelaide health study. Journal of Foot and Ankle Research, 1:2.

- Dobson et al., (2018). The three-dimensional shapes of underground coal miners’ feet do not match the internal dimensions of their work boots. Ergonomics. 61 (4), 588–602.

- Irzmańska and Okrasa (2018). Evaluation of protective footwear fit for older workers (60+): A case study using 3D scanning technique. International Journal of Industrial Ergonomics. 67, 27–31.

- Hunt et al., (2001). Inter-segment foot motion and ground reaction forces over the stance phase of walking. Clinical Biomechanics. 16, 592 -600.

- Diabetes: Australian Facts (2023). Australian Institute of Health and Welfare.www.aihw.gov.au/ reports/diabetes/diabetes/contents/about. Accessed 21/08/2023.

- Gell et al., (2011). Risk Factors for Lower Extremity Fatigue Among Assembly Plant Workers. American Journal of Industrial Medicine. 54: 216–223

- Ricci et al., (2007). Fatigue in the U.S. Workforce: Prevalence and Implications for Lost Productive Work Time. Journal of Occupational and Environmental Medicine. 49 (1), 1–10.