In Germany, the requirements for personal protective equipment (PPE) for workers are defined by the EU PPE regulation and by European and international standards based on it. DIN EN ISO 20345, an example of this, defines the requirements for safety footwear. The newly revised DIN EN ISO 20345 was published in June 2022. In this blog article, find out exactly which changes have been made and what you need to consider when buying and using safety footwear.

Safety footwear: standards and changes to basic requirements

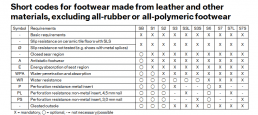

Standards for PPE products are regularly reviewed and adapted when necessary. This is also the case for DIN EN ISO 20345, which defines the requirements for safety footwear. In order for a pair of shoes to be designated as safety footwear and given the SB symbol, they must meet the following basic requirements:

- Minimum requirements for the toe cap:

- Drop test at 200 joules of test energy (20 kg from a height of approx. one metre)

- Static pressure test at 15 kilonewtons (approx. 1,500 kg of pressure)

- Inside length depending on shoe size (e.g. 39 mm in sizes 41-42)

- Corrosion resistance for steel toe caps, behaviour test for plastic toe caps when exposed to heat and chemicals

- Resistance, non-toxicity and properties of the materials used in the sole and shoe upper

- Height, ergonomics and comfort of the shoe

In addition to the above-mentioned requirements, another basic requirement has now been added:

Slip resistance on floor tiles with a sodium lauryl sulphate solution (NaLS), a type of soap solution. The symbol ‘Ø’ is used if the test cannot be carried out, for example because the shoe has metal spikes.

What additional requirements does EN ISO 20345:2022 now specify?

Alongside the basic requirements for safety footwear, there are additional requirements and provisions for various workplace hazards. Changes were also made here when the standard was revised during the second quarter of 2022.

Slip resistance

The slip resistance test procedure for safety footwear and the corresponding certification have been changed. The previous certifications ‘SRA’, ‘SRB’ and ‘SRC’ will no longer be used; instead, the certification ‘SR’ will now be used if the shoe passes a slip resistance test on a ceramic tile with glycerine. In addition to the flooring used to carry out the test, the test procedure has also been modified.

Penetration resistance

The term ‘penetration resistance’ for describing safety footwear will now be replaced by the phrase ‘puncture resistance’. The puncture resistance test will now be carried out on the basis of ISO 22568-3 and ISO 22568-4 instead of EN 12568.

New symbols for the certification of safety footwear for puncture resistance have also now been added:

| Symbol | Description |

| P |

|

| PL |

|

| PS |

|

Resistance to oil and petrol

Resistance to oil and petrol is no longer included in protection classes S1 to S5. Instead, the special symbol FO will now be used.

Water penetration and absorption of the shoe upper material

The additional requirement WRU (water-resistant uppers), which describes the water-repellent effect of the shoe’s upper, has been changed to WPA.

Additional protection classes

Protection classes S6 and S7 have been added. These certify shoes that also include a waterproof feature, e.g. a membrane:

Orthopaedic safety footwear

New requirements have been defined for adapted (orthopaedic) safety footwear. Orthopaedic safety footwear has now been divided into three different types.

- Type 1: Type 1 adapted safety footwear defines models that have been fitted with adapted (orthopaedic) insoles.

Required tests for Type 1:

- Protective toe cap

- Insoles (tests for pH value, water permeability, water absorption and desorption, abrasion resistance, chromium VI)

- Other tests depending on specified additional requirements (e.g. A, C, E, HI, CI, M)

- Type 2: Type 2 are safety shoes with an adapted outsole. A shoe can be both Type 1 and Type 2.

Required tests for Type 2:

- Separation force between shoe upper and sole

- Protective toe cap

- Slip resistance

- Outsole (tests for tear resistance, abrasion resistance, bending strength, hydrolysis resistance, separating force between the layers on multi-layer shoes)

- Other tests depending on specified additional requirements (e.g. SR, A, C, E, HI, CI, M, HRO, FO)

- Type 3: Type 3 adapted shoes are custom-made safety shoes. They must meet all the basic requirements and the desired additional requirements.

New additional requirements

With regard to slip resistance, overcaps and ladder grip, optional additional requirements have been introduced.

- Scuff cap (SC): In order to determine abrasion on the overcap, a Martindale abrasion test of 8,000 cycles will be carried out. According to the test, the overcap must not develop any holes across its entire thickness.

- Slip resistance (SR): This new additional requirement tests the slip resistance of the safety shoes on ceramic tiles with glycerine. When the heel slides forward, a coefficient of friction of >= 0.19 mm is allowed. When the front part of the shoe slides backwards, a coefficient of friction of >= 0.22 mm is allowed.

- Ladder grip (LG): To offer better grip on ladders, the outsole of a safety shoe must have a transverse profile with a height of at least 1.5 mm in the ankle area.

Overview of all additional requirements:

| Symbol | Meaning | Description | Note |

| P | Perforation Resistance, Steel Midsole | Perforation resistance | Changed |

| PL | Perforation Resistance, Non-metallic Midsole, Large Nail | New | |

| PS | Perforation Resistance, Non-metallic Midsole, Small Nail | New | |

| C | Conductivity | Conductivity | |

| A | Antistatic | Antistatic properties | |

| HI | Heat Insulation | Heat insulation | |

| CI | Cold Insulation | Cold insulation | |

| E | Energy Absorption | Energy absorption | |

| WR | Water Resistance | Water resistance | |

| M | Metatarsal Protection | Metatarsal protection | |

| AN | Ankle Protection | Ankle protection | |

| CR | Cut Resistance | Cut resistance | |

| SC | Scuff Cap | Scuff cap | New |

| SR | Slip Resistance | Slip resistance on ceramic tiles / glycerine | New |

| WPA | Water Penetration & Absorption | Water penetration and absorption | Changed |

| HRO | Heat Resistance Outsole | Resistance to contact heat | |

| FO | Resistance to Fuel and Oil | Fuel/oil resistance | |

| LG | Ladder Grip | Ladder grip | New |

Should you buy new safety shoes?

Safety shoes are an important part of your personal protective equipment. To ensure they always offer optimum protection against injuries, the shoes should be in good condition. Employers’ liability insurance associations generally recommend that safety shoes are regularly replaced, particularly if they have suffered damage that affects their protective features. In some jobs however, the shoes are subjected to major wear and tear, which means they must be replaced more frequently, as required. The employer bears the costs for new work shoes. You can determine the condition of your safety shoes against EN ISO 20345 and decide whether it’s time to buy a new pair.

Here’s what you should look for when determining the condition of your safety footwear:

a) Initial but clearly visible and deep cracking affecting half the thickness of the shoe upper

b) Severe abrasion of the shoe upper material, particularly if the toe cap or midsole for puncture resistance is exposed

c) Deformation or unravelling seams on the upper of the shoe

d) Cracks that are more than 10 mm long and 3 mm deep on the outsole

e) Tread depth on outsoles where the tread is less than 1.5 mm at one point

f) Damage to the lining or toe cap

g) The gap between the shoe upper and outsole is more than 15 mm long and 5 mm deep

h) Damage to the lining or toe cap

i) Further damage:

- Bonding of two or more treads owing to melting of the material

- Reduction in the depth of a tread to less than 1.5 mm

- Melting of the outside of the tread, visible midsole

j) Pronounced deformation and compression of original insoles (if present)

k) Significant deformation of the outsole due to the effect of heat

l) The fastening does not work properly (zip, shoelaces, eyelets, hook-and-loop fastening)

Buy EN ISO 20345-compliant safety footwear from uvex

Do you need new work shoes? You’ll find the right model for your needs in uvex’s range. Explore our range of safety shoes and orthopaedically adaptable safety shoes.