Aerosols and fine dust particles are among the most insidious health risks in the working environment because they are almost invisible in the air we breathe. Even smaller and more dangerous are viruses and bacteria that enter our bodies unnoticed via the air we breathe and can, in the worst case, lead to death. Wearing respirators is therefore part of everyday life in many working environments. But how exactly do respirators work and what do they protect against? We answer this question in the following blog post.

The function of respirators

Respirators protect against aqueous and oily aerosols, smoke, fine dust, viruses and bacteria at work* – their protective function is standardised throughout Europe according to EN 149:2001+A1:2009 and rated by the three classes FFP1, FFP2 and FFP3. They are also known as particle-filtering half masks or dust masks.

The most dangerous particles can be carcinogenic or radioactive, others can damage the body’s respiratory system over decades and lead to serious illness or even death in the long term.

*Before using respirators, their suitability must be checked and ensured by means of a risk assessment.

For protection against these particles, a respiratory protection device has long been part of the personal protective equipment (PPE) in many working environments. We would now like to find out in more detail how respirators work and how exactly particles are filtered.

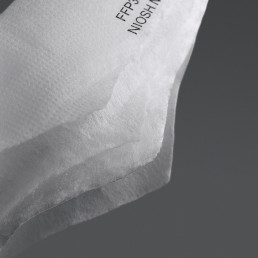

Particle-filtering respirators provide protection against particles but not against gases or vapours. The respirators are usually made entirely of multiple layers of filter material (also known as spun-bond or melt-blown material) and may be fitted with an exhalation valve. The various layers all fulfil a different purpose, from improving the look and feel of the respirator to ensuring strength, tear resistance and natural filtration.

One of the most important aspects of comfort for wearers of respirators is breathing resistance, which refers to the resistance that the wearer feels when breathing in and out – the higher the resistance, the harder the wearer’s lungs have to work. To keep breathing resistance as low as possible, the filter material must be air-permeable on one hand while still filtering particles on the other. That’s why the filter material is electrostatically charged. This enables particles that would actually be small enough to pass through the filter material to stick to it instead.

The best way to understand this is with the help of a balloon and some ground pepper: if you blow up the balloon and rub it against a piece of fabric, it becomes electrostatically charged. If you now bring the charged balloon close to the pepper, the fine pepper dust will be attracted to the balloon even from several centimetres away – it’s exactly this effect that ensures in a respirator that the air can flow through while the particles are trapped.

The protection classes: FFP1, FFP2 and FFP3

Respirators are assigned to one of three protection classes. But what exactly is the difference between these three protection classes?

They differ not according to the size of the filtered particles, but according to the number of filtered particles.

FFP1 respirators

FFP1 respirators have a filtering capacity of at least 80%, up to 4 times the respective occupational exposure limit (OEL*). Respiratory protection devices in this protection class protect the wearer against non-toxic and non-fibrogenic dusts. FFP1 respirators are therefore used in areas where the breathable air contains particles that will not usually make the worker ill if inhaled, but which may cause an annoying odour or briefly irritate the respiratory tract.

FFP2 respirators

FFP2 respirators filter at least 94% of particles in the air, up to 10 times the respective occupational exposure limit (OEL*). Respirators in this protection class protect the wearer from solid and liquid particles, dust, smoke and aerosols that are harmful to health. FFP2 respirators are used in areas where fibrogenic particles are present, which can cause short-term irritation of the respiratory tract and long-term damage to lung tissue.

FFP3 respirators

FFP3 respirators filter at least 99% of particles, up to 30 times the respective occupational exposure limit (OEL*). They protect the wearer from dust, smoke and aerosols that are toxic and harmful to health. FFP3 respirators are used in working environments in which carcinogenic or radioactive substances are handled. These can be pathogens such as viruses, bacteria or fungal spores.

*OEL = occupation exposure limit (OEL). This is the average concentration of a substance in the breathable air at the workplace up to which no harm (chronic or acute) is to be expected if the employee works there for eight hours a day, five days a week.

The more particles that need to be filtered out, the more layers of filter material used – this means that respirators in higher protection classes are always thicker, which results in a higher breathing resistance.

In order to further reduce the breathing resistance of FFP2 and FFP3 respirators, uvex has developed unique high-performance respirators which, in addition to lower breathing resistance, also ensure a better climate inside the respirator: the uvex silv-Air e 7333 FFP3.

Do you have more questions about respiratory protection and its function? Read more in our FAQs on respiratory protection. We are also happy to advise you personally on our uvex respirators and the relevant protection classes.

The risk of inhaling harmful particles, vapors and gases is very high in many industries and that is a big threat to worker safety. Consistent use of Respiratory Protection Mask is an important part of the strategy to protect yourself from inhaling infectious particles, preventing the spread of respiratory infection between each other.