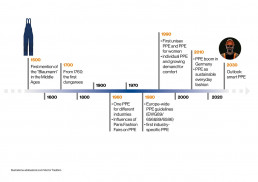

In a work context, the German expression ‘blau machen’ (lit. ‘to make blue’) can mean various things, including to call in sick. In the context of personal protective equipment (PPE), however, the mostly likely thing that comes to mind is the infamous boilersuit (known in German as a ‘Blaumann’). The term was first used in the late Middle Ages. At that time, however, the term referred to the simple fabric garments, usually overalls without a belt, worn by people working in various trades.

Several centuries later, during the Industrial Revolution, the first dungarees appeared. But even these have very little in common with PPE as we know it today. In fact, PPE is constantly changing – both in terms of its appearance and its functionality. That’s why it’s high time we put these developments in context and took you on a little journey through the last few decades.

Beide Situationen hängen mit den meisten der nachfolgend skizzierten Fehler zusammen. PSA-Verantwortlichen kommt daher gemäß Arbeitsschutzgesetz (§ 3, ArbSchG) die Aufgabe zu, ihre Teams bedarfsgerecht auszustatten und zugleich für die korrekte Anwendung der PSA zu sorgen. Damit das gelingt, sollten Sie die folgenden Punkte im Blick behalten.

PPE past and present: features and influences

But before we open the time capsule, it’s worth clarifying what influences there are on PPE and how PPE changes over time. Across the eras, four main areas can be identified:

- Appearance: To put it bluntly: the boilersuit, once a classic, is now out. In the 21st century, PPE instead serves as fashionable workwear intended to complement a company’s corporate image. In addition, since the beginning of the 2000s, an increasing number of manufacturers have been making PPE for women or at least unisex variants. PPE items are now available in various fits, cuts and clothing sizes as well as colour variants, and increasingly frequently also with multifunctional extras such as telephony or radio functions. Today’s workwear is often influenced by street and outdoor clothing when it comes to design and colour.

- Safety: According to the German Statutory Accident Insurance (DGUV), the number of workplace accidents (fatal and non-fatal) reported annually in Germany between 1986 and 2020 has almost halved – from nearly 1.4 million to around 0.75 million. The Occupational Health and Safety Act (ArbSchG), which came into force in 1996 and for the first time obliged German employers to provide PPE for their employees, has had a significant influence on these figures. At the same time, thanks to more comprehensive suitability and quality tests as well as the increased development of activity-specific PPE, levels of safety and protection in many sectors have also risen even further. The current EU (2016/425) PPE regulation includes all the guidelines for this.

- Functionality: Ever more lightweight, moisture-wicking or breathable – the range of materials for protective suits is growing steadily. While in the last century, PPE was made mostly of heavy cotton or polyester, it is now usually made of lighter materials like nylon or elastane. These and other high-tech materials adapt to the various requirements, meaning that today’s PPE is usually quick-drying, wind-proof, water-repellent and breathable. In terms of function and fit, it is tailored to the working environment and the person wearing it. Depending on their PPE categorisation, PPE products are now subject to various conformity assessment processes.

- Sustainability: Sustainability in the PPE sector now includes the entire product life cycle as well as the whole value creation chain. This starts with the cultivation of the raw materials for making the product and ends with the disposal of the product. For example, eco-friendly workwear ranges such as uvex suXXeed greencycle planet are completely compostable – from the yarn and the dye to the buttons. The PPE can therefore be returned fully to the ecosystem once it has been discarded.

Another important aspect here is the issue of durability. While during the 20th century PPE product lines were still usually used within a company for an average of 15 to 20 years, today they are usually replaced every six to eight years. In addition, the latest PPE regulation means that PPE manufacturers must have their products tested by a certification authority every 5 years or carry out their own checks to ensure that a PPE product line still meets all the current requirements.

Equipped with the knowledge about these major influences on PPE, let’s head back to the time capsule and let ourselves be transported 50 years into the past.

Late 1960s and 1970s: first influences of fashion on PPE

And whoosh, here we are. Welcome to the age of the hippies, with their long flowery dresses and fringed leather waistcoats. But of course 1960s and 70s PPE wasn’t quite as edgy and dazzling as the fashionable everyday clothing of the period. In fact, until the 1970s, the same workwear and PPE was offered for all sectors, while specialised items were usually only for guild clothing. Nevertheless, inspired by Parisian fashion shows, even PPE manufacturers began to develop a little fashion sense. However, numerous eyewitness accounts from these decades prove that there was still a way to go, particularly when it came to PPE wearer comfort.

For example, clogs, i.e. commercially available wooden shoes, were still popular in some production halls until the end of the 1970s. Head protection combinations basically consisted of a simple industrial safety helmet. Visors for protecting the face were drilled onto the helmet, if they were used at all. Forestry or sawmill workers usually carried out their jobs in work clothing that had no cut protection for the legs and lower abdomen – something that is unthinkable today. If a protective fabric, for example in the form of a cut protection apron, was added, this was usually very heavy or even hindered the wearer from carrying out their work activities.

Nevertheless, these decades were crucial in making PPE safer. Because despite all the shortcomings in practice, standards for fabric testing when manufacturing protective clothing as well as flammability or fire classes for PPE classification were introduced during this time. Safety experts also looked more closely at the chemical protection of PPE and, as a result, drew important conclusions about its properties.

1980s: PPE for various sectors

The 1980s marked a legal turning point: the European Union passed two PPE directives at the end of the decade (89/686/EEC and 89/656/EEC), thus harmonising the regulations that had previously applied in the individual member states. Basic health and safety requirements for PPE and for placing PPE on the market were subsequently defined. Central to this period was the development of sector-specific PPE. For fire fighters for example, particular emphasis was placed on increasing the visibility of their PPE: their protective clothing was equipped with silver reflectors. During this phase, the first flame protection jackets with matching trousers, as well as hinged plastic visors for face protection, also became available.

In terms of appearance, the PPE of this era was defined in particular by a straight cut, while snap fasteners were the dominant type of closure on work jackets. Like lab coats, these usually also had a large turn down collar. Meanwhile, artificial fibres like polyester had to contend with a rather poor reputation in those days.

1990s and 2000s: PPE for women

This changed dramatically, especially at the end of the last century. Now, in addition to cotton and mixed fabrics, polyester was increasingly used for the production of PPE textiles. Hook-and-loop fasteners became the closure of choice on work and PPE jackets for most manufacturers, mainly because they were very good for closing pockets.

Any visual changes were merely side effects of a much more profound change, however. Particularly from the end of the 1990s, old gender stereotypes in hitherto male-dominated professions were gradually breaking down – a development that continues to this day. The study ‘Changes in the percentage of women in male-dominated professions from 2004 to 2015’ by the German Federal Institute for Vocational Education and Training provides ample proof of this. The authors of the study found that the percentage of young women in male-dominated professions – i.e. in professions in which men make up over 80 per cent of the workforce – grew by an average of over two per cent a year during this period. This trend also made it more attractive for manufacturers of workwear or PPE to offer additional options especially for women.

However, a survey by the Vienna Chamber of Labour published in 2009 showed that the employees surveyed were not very familiar with PPE designed especially for women. Many companies were instead focussing on adapting the design of their PPE products so that they could be sold as unisex collections. Independently of this, PPE wearers’ demand for comfort continued to steadily increase during these two decades.

However, as a result of the global economic and financial crisis from 2007, the wearing and use cycles of PPE in companies became significantly longer for several years. The price sensitivity of PPE customer groups also increased noticeably. This is undoubtedly due to the fact that during this period PPE managers were looking for potential savings in a difficult economic environment.

From 2010: PPE as a sustainable lifestyle product

After years of global crisis, the market for workwear and PPE began to grow steadily again from 2010. For example, according to data from the BTE Textile Trade Association, gross workwear sales increased in Germany from a previous EUR 810 million to EUR 1,045 billion between 2010 and 2018 alone. In addition to this, the sector report by market research institute Marketmedia24 revealed that workwear sales figures for 2021 were around 20 per cent higher than those for 2010, and a good five per cent above the comparative value in the PPE sector. This growth is due not least to the fact that safety footwear and other PPE items are becoming increasingly more fashionable and thus more attractive. Since then, there has been repeated talk of the so-called fashionisation of PPE.

From safety shoes that look like trainers to colourful work trousers customised for a company – the PPE market is becoming more diverse, with functional clothing now often also worn as an everyday outfit by employees.

The trend for increased sustainability, which has noticeably spread to the PPE sector in recent years, also plays a role here. PPE manufactured using resource-saving processes and long-lasting, environmentally friendly materials is today the norm among professional suppliers and is in keeping with the primary protective function of PPE. Two key sustainability criteria for PPE and workwear in general play a role here:

- Environment: Resource-saving manufacturing processes, minimised environmental impact, no pollutants and the ability to recycle the products must be considered here.

- Social aspects: These include fair working conditions at the suppliers, which can be achieved through minimum prices for farms in the cotton sector, for example.

With the first fully compostable workwear collection uvex suXXeed greencycle planet, uvex is taking sustainability even one step further. From renewable energies and short transport routes to high social standards, all criteria are tested and certified by an independent institute.

Did you know?…A market study by research company macrom Marketingresearch & Consult in 2021 showed that the outbreak of the COVID-19 pandemic in Germany in 2020 led to a division of the PPE market. While the demand for PPE products to help control the pandemic downright exploded, the lockdown periods contributed to a significant decline in sales in many product areas.

From 2020: the move towards smart PPE

It’s nice to be back in the present day. As our little trip through time clearly showed, PPE has gone through many changes over the years. Today, modern fabrics and materials offer both maximum wearer comfort and improved protection against heat, cold and wet conditions. In addition, PPE now weighs hardly anything, is easy to clean, looks stylish and can be adapted to individual requirements.

Looking ahead, the integration of digital technologies in PPE is also set to come into focus. For example, it’s conceivable that sensors for monitoring vital functions or environment data will increasingly be integrated into PPE textiles. This is already a reality in some areas. A well-known example is innovative PPE for fire fighters, with the help of which the vital signs of emergency personnel can be monitored. If a critical threshold value is exceeded or undershot, the head of operations is automatically informed and can react promptly. Initial tests and studies with smart PPE in the construction industry are also ongoing. From protective jackets with an integrated airbag for activities on ladders to safety helmets or safety spectacles that check whether employees are wearing the right protective clothing, there are many different starting points and approaches. Even illuminated protective clothing, which switches on automatically in poor light, is no longer a mere pipe dream.

However, as all these technologies have not yet been widely tested or made available, in the near future, PPE manufacturers must consider two main legal questions and the issues that come with them:

- How can it be ensured that data is collected and processed by smart PPE in a way that complies with the GDPR and that privacy rights are respected?

- How exactly should smart PPE be certified in accordance with the EU PPE regulation, and should the requirements be identical for all sectors and fields?

Irrespective of the points that still need to be clarified, PPE experts and safety professionals generally agree that sooner or later, smart PPE will be a part of everyday life. How quickly these changes will take place however is difficult to predict and depends on various developments in society as a whole (including the general economic situation). It’s safe to say that the future of PPE will be just as fascinating as its past.

Would you like to learn more about our product technologies and digital approaches for smart PPE? Then take a look at the respective sub-pages and be inspired by our ‘Made in Germany’ innovations.