In industrial food processing – as well as in all other areas in which food is handled – selecting the right safety gloves is of particular importance. Mainly to avoid injuries to the hands and skin, but also to avoid any health risks posed to consumers from contaminated foodstuffs. To this end, food law regulations play an equally important role in ensuring adequate protection against one of the most common forms of injury: cut injuries.

Basic requirements of safety gloves

In fundamental terms, safety gloves used for food processing and production applications must be manufactured in such a way that substances released pose no human health risk. Food producers must take all necessary measures to exclude the risk of contamination and guarantee the health of consumers. Standards for hygiene and cleanliness of products form the basis of this. The legal requirements for safety gloves are therefore accordingly strict, as the gloves themselves could also represent a source of contamination. Regulation EC 1935/2004 defines the general framework of requirements for materials and objects which come into contact with foodstuffs. The requirements for safety gloves set out in Regulation (EC) 1935/2004 were substantiated in Regulation (EU) 10/2011.

As an active partner in the field of personal protective equipment (PPE), uvex offers application-oriented solutions for the diverse areas of activity in the food industry. The key to optimal personal and product protection lies in our broad product range, in our customer support which is equally professional and personal at all times as well as in the extremely high standards of quality we place on our own products.

Application-oriented safety glove selection

Activities in the food industry are just as varied as the requirements to which the necessary PPE is subject. In order to guarantee optimal protection for the skin and stave off any contamination risks, safety gloves must be specifically adapted to their respective applications. A precise risk and workplace analysis is of utmost importance in this. To determine which safety glove is the right one for each application, we support our customers as an active partner – and our versatile portfolio allows uvex to cover a huge range of application areas:

| AQUEOUS PH > 4,5 | ACIDIC PH < 4,5 | ALCOHOLIC | FATTY | DRY, NON FATTY | |

|---|---|---|---|---|---|

| Examples | non-alcoholic beverages, fruit, eggs, vegetables, crustaceans | vinegar, yeast, milk, yoghurt | wine, spirits, liqueurs | olive oil (R1), mutter and margarine (R2), fish, cheese and baked goods (R3), meat, pultry (R4), sandwiches and fried food (R5) | bread, pasta, rice, tea, spices, pulses |

| uvex profi ergo | YES | YES | YES | YES (R1 to R5) | YES |

| uvex contact ergo | YES | YES | YES | YES (R1 to R5) | YES |

| uvex phynomic C3 | YES | YES | YES | YES (R1 to R5) | YES |

| uvex C5 | YES | YES | YES | YES (R1 to R5) | YES |

| uvex rubiflex (orange) | YES | YES | YES | YES (R1 to R5) | YES |

| uvex rubiflex S (blue/green) | YES | YES | YES | YES (R1 to R5) | YES |

| uvex profastrong NF 33 | YES | YES | YES | YES (R2 to R5) | YES |

| uvex u-fit | YES | YES | YES | YES (R3 to R5) | YES |

| uvex phynomic foam | YES | YES | YES | YES (R5) | YES |

| uvex phynomic lite (w) | YES | YES | YES | YES (R1 to R5) | YES |

| uvex unilite hermo | YES | YES | YES | NO | YES |

| uvex u-fit strong N2000 | YES | NO | YES | YES (R3 to R5) | YES |

| uvex u-fit lite | YES | NO | YES | YES (R3 to R5) | YES |

Table: Application areas for uvex safety gloves in the food industry

Cut injuries in food processing

Sharp objects pose a constant risk to our hands, especially in the food industry with its wide-range of activities. Above all in food processing, industrial kitchens and private households, there is an increased risk of cut injuries when dealing with food. For example, this risk is present when cutting up meat or dicing vegetables with a sharp knife, when sharpening knives and also when changing knives in industrial scenarios.

Hand injuries from cuts or superficial skin injuries are, however, among the most common cross-industry consequences of accidents. The official accident statistics from the DGUV (German Social Accident Insurance) clearly reflect the above-average frequency of injuries to thumbs and index fingers.

Cut injury

Superficial skin injury

Thumb

4,210

15,141

Index finger

556

19,716

Middle finger

268

9,060

Ring finger

119

4,135

Little finger

106

4,390

Middle hand

314

5,783

Entire hand

824

4,391

Hand injuries due to contact with sharp objects (source: Referat – Statistik – Deutsche Gesetzliche Unfallversicherung (DGUV), Berichtsjahr 2014)

To avoid cut injuries, it is important to wear cut-resistant safety gloves during these activities. Effective hand protection offers wearers the perfect balance between reliable protection, great wearer comfort and the flexibility required for unencumbered handling. uvex is continually developing its innovative fibre and coating technologies for safety gloves, in order to perfect exactly this balance. In doing so, we are combining technology fibres, such as HPPE or glass, for example, which possess high cut resistance properties and increase tear resistance, with comfort fibres, which offer a high degree of wearer comfort and ensure pleasant climate properties inside the glove.

uvex and HexArmor cut protection gloves

With the latest generation of the patented uvex Bamboo TwinFlex® and the use of Dyneema® Diamond, two high-performance cut protection technologies (in accordance with EN 388:2016 cut protection level C and D) for uvex safety gloves are now available. The strategic partnership with the U.S.-based hand protection specialists HexArmor also expands our cut protection range. The patented SuperFabric® technology used in many HexArmor products, offers a very high degree of cut resistance and above all puncture resistance. This means that the products are perfectly suited to being used for industrial food processing applications.

Two pairs of safety gloves specially developed for the food industry are the uvex phynomic C5 and HexArmor NXT 10-302:

The uvex phynomic C5 is perfect for applications requiring maximum cut protection, secure grip and precision. The thin, breathable coating and the fine-knit glove lining guarantee a good fit for delicate, flexible work. Independent tests confirmed the good skin tolerability of the gloves.[1]

uvex phynomic C5 with cut-resistant DSM Dyneema® Diamond Technology

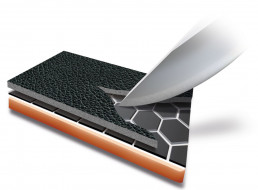

The HexArmor NXT 10-302 is perfectly suited to food preparation with knives on account of the SuperFabric® technology used around the thumb, index finger and middle finger areas. Specially designed, multi-layer guard plates effectively protect against cut and stab injuries.

uvex phynomic C5 with cut-resistant DSM Dyneema® Diamond Technology

Further information on the products and technologies:

Contact:

UVEX SAFETY Gloves GmbH & Co. KG

Elso-Klöver-Str. 6

21337 Lüneburg

E-Mail: gloves@uvex.de

[1] Independently and dermatologically tested by proDerm – Institute for Applied Dermatological Research GmbH, Hamburg. Further information on the certification and the applied testing criteria can be found at: https://www.uvex-safety.com/en/knowledge/certificates/proderm/