Questions and answers on the subject of respiratory protection

Respiratory protection products fall under PPE category iii, which means that the products provide protection against irreparable damage/disease and death. Because of this, training is mandatory for products in this category. The training covers aspects such as how to correctly fit and remove the respirator.

The employer is responsible both for selecting an appropriate respirator and for organising the training.

You can find more information on choosing the right mask here.

According to the Robert Koch Institute, the most important and effective ways to protect yourself are: “Self-isolation if you are ill, practising good hand hygiene, complying with rules relating to coughs and sneezes and practising social distancing (staying at least 1.5 metres away from others)”. If you are treating a patient, the authorities recommend other measures, including wearing a close-fitting, multi-layer mouth and nose mask.

The minimum recommended protection level for respiratory protection is FFP2 (based on the European standard) or N95 (based on the American standard). Masks in protection categories FFP3 or N99 provide a higher level of protection.

Further information can be obtained directly from the Robert Koch Institute or the World Health Organization.

Particle-filtering respirators provide protection against particles but not against gases or vapours. These masks are usually made entirely of multiple layers of filter material and may be fitted with an exhalation valve.

The various layers all fulfil a different purpose, from improving the look and feel of the mask to ensuring strength, tear resistance and filtration.

One of the most important aspects of comfort for wearers of respirators is breathing resistance, which refers to the resistance that the wearer feels when breathing in and out – the higher the resistance, the harder the wearer’s lungs have to work.

To keep breathing resistance low, the filter material must be air-permeable on one side while still filtering particles on the other. For this reason, the filter material is electrostatically charged. This allows small particles that are actually small enough to pass through the filter material to stick to it.

The difference between the three protection categories is not the size of the particles filtered out, but the number of particles filtered out.

FFP1 filters out at least 80 percent of particles; FFP2 manages 94 percent while FFP3 achieves 99 percent.

The more particles that need to be filtered out, the more layers of filter material used for the mask. This means that masks in higher protection categories are always more dense, which results in a higher breathing resistance.

Mouth and nose masks are often referred to as surgical masks. They are designed to prevent droplets and bodily fluids excreted by the wearer from being transmitted into the environment. However, these masks do not provide sufficient protection for the wearer.

Unlike respiratory protection products designed in line with EN149, these masks are not considered personal protective equipment. uvex masks are primarily designed to protect the wearer, which is why factors such as achieving a close fit are incredibly important. uvex respirators are capable of filtering out the smallest particles and droplets from the ambient air to provide reliable protection for the wearer.

uvex focuses on the manufacture of personal protective equipment. For this reason, our range only includes respirators that satisfy European Standard EN149; we do not sell surgical masks.

The German Institute for Occupational Safety and Health has compiled a detailed comparison of the various types of mask available.

The exhalation valve opens when the wearer breathes out, significantly reducing breathing resistance and making it more comfortable to wear the mask for an extended period of time. The warm, moist air from the wearer’s lungs is quickly cleared from the mask.

When the wearer breathes in, the valve closes and reseals itself and the wearer breathes via the material surface. The exhaled air is not filtered, but emitted directly into the environment. This means that there is a risk of droplets from the wearer being transmitted into the environment unfiltered.

Single-use respirators are designed to be worn for a single shift lasting up to eight hours.

If your job involves handling toxic substances, the masks must only be used once, which means that every time the mask is taken off, it must be replaced with a new one (when working with viruses/bacteria or carcinogenic substances, for example). For hygiene reasons, single-use respirators must only be used for a maximum of one day and worn by only one person.

Unfortunately, it is not possible to decontaminate or re-use uvex respirators.

Respirators are made from electrostatically charged filter material (see also: How does a respirator work?). Various processes, including radiation and steaming, can destroy this material. The protective function of the mask cannot be guaranteed after exposure to these processes.

For this reason, we strongly advise against any re-use of masks. Respirators are designed as single-use products.

The filtration effect of single-use masks is achieved through the electrostatic charge applied to the filter material.

As the electrostatic charge will gradually fade over time, uvex single-use respirators must be used within 36 or 60 months of production (depending on the model).

The expiry date is clearly indicated on each box. The masks should not be used after this date.

Unfortunately, as uvex does not manufacture mouth and nose masks, we cannot provide any instructions.

As part of the approval process under the EN149 standard, the mask is exposed to various conditions. The mask is exposed to a range of different temperatures and humidity levels and must continue to protect the wearer in these conditions.

Please take note of the storage conditions and information in the instructions for use that accompany the mask. In normal conditions, the respirator can withstand some level of humidity. In everyday use, moisture – such as water from drops of rain – does not present a major risk.

However, the mask should never be submerged in water.

When fitting a respirator, achieving a close fit is essential to the wearer’s safety. Instructions for correctly fitting the masks can be found in the instructions for use and on the packaging.

You can also consult our instruction videos:

uvex flat-fold masks

uvex cup-style masks

During the COVID-19 pandemic, we have unfortunately seen increasing numbers of fake products entering circulation. We therefore advise you to only purchase products directly from uvex or authorised dealers and partners.

Locate your nearest partner here.

You can also check the following points:

- Unless otherwise specified by uvex, uvex products are always delivered in uvex packaging.

- uvex respirators are always marked with the word uvex, the relevant standards and the CE marking.

- Each pack will include a uvex instruction manual.

- uvex masks are sold in pre-packaged units. uvex does not sell individual masks.

- The date of manufacture and the date of expiry will be printed on the packaging.

- Thanks to our strict quality control processes, it is very unlikely that you will receive products that are unpackaged, incorrectly assembled or with errors on the packaging or in the instructions.

If you have concerns about any of these points, please contact our customer service team to confirm whether or not your mask is a genuine uvex product: safety@uvex.de.

You can find out more about how to tell if it is a genuine uvex product or a correctly approved respirator in our blog post or here for download.

If you are interested in uvex products please contact:

safety@uvex.de

Phone: +49 800 66 44 893

There are a number of subjective and objective means of testing a respirator’s fit. This information may help you to find the type of mask which best fits your particular face shape. Detailed information on the testing procedures is available by following the link below: Proper Use/ Fit-test

The “D” certification for disposable respirators signals that it fulfils an additional requirement under the EN 149 standard, the dolomite dust test. This tests whether the mask’s breathing resistance remains low after being loaded with dolomite dust. For this reason, the “D” certification is proof of the filter material quality and confirms that the mask can be worn in environments with even extremely high dust exposure over a long period of time. Details of the EN 149 standard can be found here: Standards/regulation

In accordance with the EN 149 standard, an “R” certification for a disposable respirator stands for “reusable” and “NR” for “non-reusable.” In determining whether a mask can be used for a second shift, its cleanability is tested. If it is deemed cleanable, it is designated “R”, if not, it is marked “NR”.

The additional filter containers significantly reduce the breathing resistance and work in conjunction with the inhalation valves to effectively regulate the temperature inside the mask.

Additional details can be found here: Technologies

When wearing a respirator, operating instructions and any corresponding national guidelines and regulations must be observed. In Germany, for example, BGR 190 is the relevant standard for the use of respiratory protection.

A brief overview of this can be found here: Standards/regulation

The combination of respirator and uvex safety goggle models is determined by the wearer’s face shape. To make it easier for you to find the right match, we have carried out extensive wearability tests and summarised the results here: Eyewear-respiratory-combinations

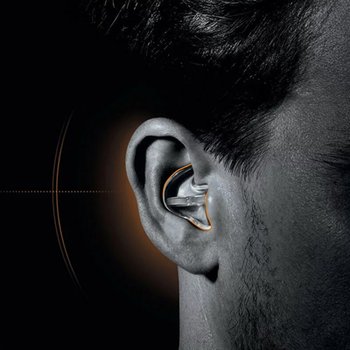

The sealing lip and adjustable nose clip establish a close fit on the face, especially around the nose area. In addition to respirators with a sealed lip and nose clip, uvex also offers completely metal-free masks. These masks feature innovative 3D nose technology: a special ergonomic nose shape ensures that the mask still fits securely on the face even without a sealing lip – the advantage is that wearers do not need to worry about adjusting the nose clip.

The occupation exposure limit (OEL) is the acceptable time-weighted average concentration of a hazardous substance in workplace air at which no acute or chronic harm is caused to employees’ health. In determining this limit, it is assumed that an employee would be exposed for eight hours per day, five days per week for the duration of their working life.

The OEL was introduced in Germany on 1 January 2005, alongside the revision of the Ordinance on Hazardous Substances (GefStoffV). It replaced the previous maximum workplace concentration (MAK) and technical recommended values (TRK). The previous MAK and/or TRK values can still be used to calculate the hazard level of a workplace until the OEL is integrated into all technical regulations.

The CAS registry number is an international standard identification system for chemical substances. Each chemical substance in the CAS database (which also contains bio sequences, alloys and polymers) has its own unique CAS registry number.

All uvex particle-filtering masks fall into group 1 of the respirators, as they weigh less than 3 kg and the inhalation and exhalation resistance are significantly less than 5 mbar.

For group 1, an occupational medical examination must be offered by the employer; for groups 2 and 3, this is mandatory.