Standards and Directives

Of course, based on regulation (EU) 2016/425 on personal protective equipment (PPE) our products meet all the necessary standards, and not just that – we always require that little bit more from our products. This ensures the extra safety that our customers – rightly – expect from us.

DIN EN 388:2003 – Safety gloves against mechanical risks

The European standard DIN EN 388:2003 describes the requirements, test methods and labelling of safety gloves against mechanical risks when carrying out work. The test methods laid down can also be applied to arm protectors (in other words, on parts of protective clothing that are not firmly connected to glove or protective clothing).

In the same way as the test results, the safety gloves are classified with a performance level in relation to each of the individual mechanical hazards. The relevant values (number from 0 to 5, with 4/5 being the best) can be seen next to the pictogram of the glove.

The mechanical risks and stresses and/or their test methods are defined in DIN EN 388:2003 as follows:

- Resistance to abrasion:

To test the safety glove's resistance to abrasion, the material is treated with sandpaper under pressure. The number of cycles needed to abrade a hole in the material serves as a benchmark.

(Highest performance level 4 = 8,000 cycles) - Blade cut resistance:

To check the blade cut resistance of a safety glove, a rotating circular blade is used, which cuts through the glove at a constant speed. Comparison with a reference material serves as a benchmark and a resulting index.

(Highest performance level 5 = index 20) - Tear resistance:

To check tear resistance, the material of the safety glove is firstly slit. The force needed to tear the material serves as a benchmark.

(Highest performance level 4 = 75 Newtons) - Puncture resistance:

To test the puncture resistance, the glove is punctured with a nail (established dimension). The force used serves as a benchmark.

(Highest performance level 4 = 150 Newtons)

| performance class | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| index | ≥ 1,2 | ≥ 2,5 | ≥ 5 | ≥ 10 | ≥ 20 |

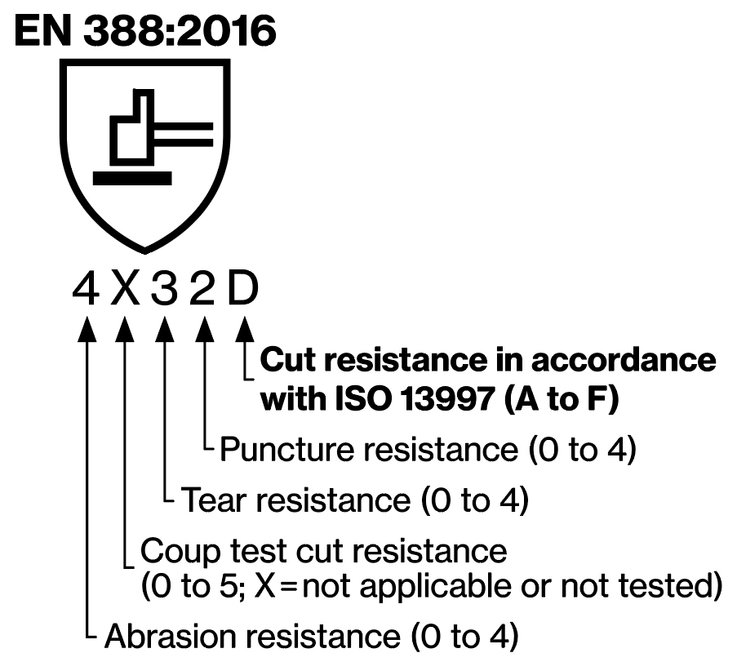

EN 388:2016 – Modification to the standard for cut protection gloves

Protection classes for cut protection gloves were previously assigned in Europe in accordance with standard DIN EN 388:2003. Due to the continuous development of technical materials – so-called ‘high-performance fibres’ – it has become necessary to adjust the methods used to test and classify these products. These changes have been implemented in standard DIN EN 388:2016.

Test procedure in accordance with EN 388:2016/ISO 13997

- Relates to cut protection gloves made from materials that cause the blades to become blunt (i.e. glass and steel fibres).

- Additional test procedure in accordance with ISO 13997: Determination of resistance of the glove to cutting by a sharp object through single contact under higher force

- Here, a long, straight blade is drawn once over the test piece. The minimum force required to cut through the test piece after 20 millimetres is determined in the process.

- The result is given in newtons (N) and assigned to a cut protection class.

| Performance class | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Newton value | ≥ 2 | ≥ 5 | ≥ 10 | ≥ 15 | ≥ 22 | ≥ 30 |

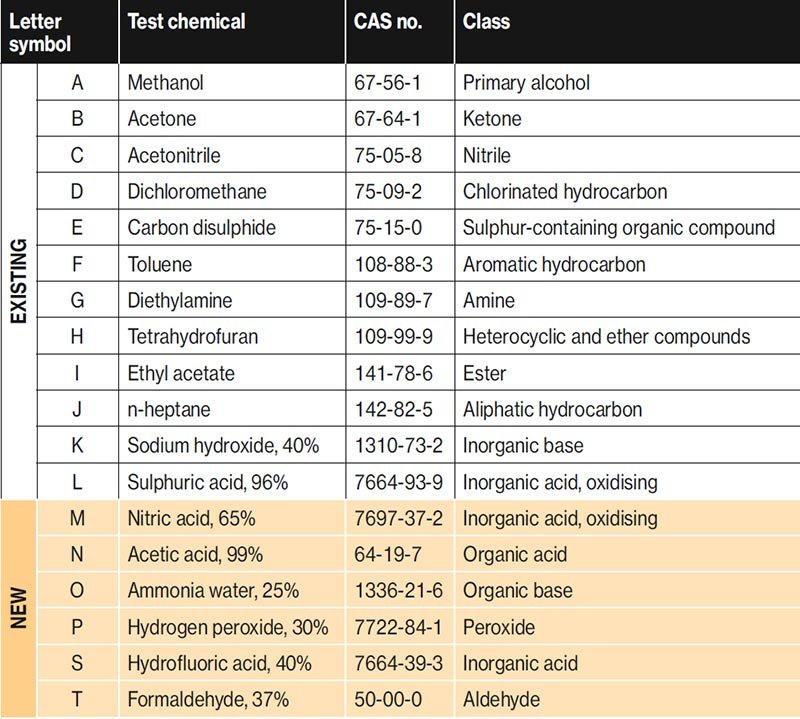

EN ISO 374-1:2016 – Modification to the Standard for chemical safety gloves

Chemical safety gloves must meet the requirements of European standard EN ISO 374-1. This standard has undergone fundamental changes in terms of certification.

Part 1 (Terminology and performance requirements for chemical risks) contains important modifications:

- Expansion of test chemicals from 12 to 18

- Omission of beaker glass for “water-resistant safety glove with low protection against chemical risks”

- Standardisation of types of gloves into type A, B or C

- Modification to labelling on the product: Pictogram of Erlenmeyer flask with differing number of letters for test chemicals depending on type

New labelling of safety glove:

Permeation resistance of type A: at least 30 minutes each with at least 6 test chemicals.

Permeation resistance of type B: at least 30 minutes each with at least 3 test chemicals.

Permeation resistance of type C: at least 10 minutes each with at least 1 test chemical.

Expansion of test chemicals: The test catalogue has been expanded in accordance with the new standard.

As before, the application guidance of the manufacturer is of great importance. The specific protection requirement must be determined as part of a risk assessment of the actual works process taking account of the specific application conditions. A designated safety professional must define the individual requirements and secure conformation of the specific protection levels of the safety gloves from the manufacturer’s data sheets. With the Glove Expert, uvex provides a multilingual, online platform to search for individual permeation times. In addition, experienced staff are available on-site and in the centre of expertise for safety gloves in Lüneburg to provide advice on all questions relating to safety gloves for protection against chemical risks.

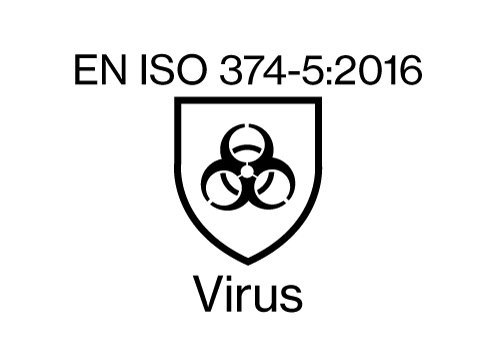

DIN EN 374-5: 2016 Standard for safety gloves to protect against dangerous chemicals and micro-organisms

To protect against microorganisms such as bacteria, fungi and viruses, safety gloves must undergo and pass special penetration tests in accordance with ISO 16604:2004 (method B). Only then may they be marked with the pictogram for EN ISO 374-5.

Labelling of safety gloves

Variant 1:

Protects against bacteria, fungi and viruses

Variant 2:

Protects against bacteria and fungi

Labelling on the glove

- Name of the manufacturer

- Glove Product Name

- Performance classes, mechanical

- CE conformity mark

- No. of Test Institute

- Letters symbolise test chemicals against which the glove has a protection index of at least class 2.

- Pictogram with designation of standard

- Note enclosed instructions for use

- Glove size

- Expiration date

- Manufacturer address

Permeation

| Time measured to penetration | Protection index |

| > 10 min | Class 1 |

| > 30 min | Class 2 |

| > 60 min | Class 3 |

| > 120 min | Class 4 |

| > 240 min | Class 5 |

| > 480 min | Class 6 |

Permeation refers to molecular penetration through the safety glove material. The time required by the chemicals to permeate, determines the performance class in accordance with EN ISO 374-1. The actual period of protection at the workplace may vary depending on real-time process factors.

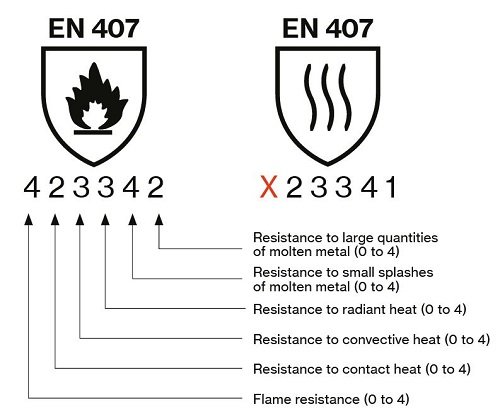

DIN EN 407:2020 Standard for safety gloves providing protection against thermal risks — heat

The European standard DIN EN 407 regulates the requirements for safety gloves that provide protection against thermal risks in applications involving heat. Safety gloves certified according to this standard protect the wearer against contact heat, radiant heat and small splashes of molten metal, for example.

However, this does not apply to the specific use of safety gloves in firefighting. According to DIN EN 407, heat protection gloves must have the following features:

- low flammability and low flame propagation

- low heat transmission (protection against radiant, convective and contact heat)

- high temperature resistance

Important changes to standards!

In the latest version of DIN EN 407: As of 2020, the first performance class is no longer named “resistance to flammability”, but is now called “limited flame spread”. If the glove has not been tested for this, a new pictogram is used (see above right). However, there are no changes to the performance classes.

The test described in DIN EN 407 assigns safety gloves a performance class in relation to each of the individual thermal hazards. It is important that the glove does not come into contact with open flames if it does not meet the criteria of performance class 3 in the limited flame spread test.

DIN EN 511 – Protection from cold

Minimum requirements for safety gloves in relation to protection from cold are regulated in standard DIN EN 511. The gloves certified under this standard are intended to protect the wearer from convective cold (penetrating cold) and contact cold (direct contact).

As with protection from thermal and mechanical risks, the safety glove is classified into different performance levels for individual aspects. The performance levels are indicated with a number from 1 to 4 next to the pictogram, where 4 is the highest level.

Determination of performance levels for safety gloves against cold:

- Convective cold:

Measuring the quantity of energy needed to maintain the temperature of a heated hand model (30 to 35 °C) with a safety glove in relation to a constant room temperature. (Calculation of the thermal insulation properties based on the temperature of the hand model, room temperature and energy required to maintain the temperature.) - Contact cold (Test in accordance with ISO 5085):

Determination of thermal resistance of the safety gloves with a cold and a hot plate. The glove material is placed as an insulator between both plates and the change in the temperature gradient acts as a measurand (comparison with normative reference).

The glove can also be tested for water permeability in accordance with EN ISO 15383. If no water permeates into the glove over a 30-minute period, this test is deemed as passed (no specific performance levels).

DIN EN 16350:2014 – Safety gloves, electrostatic properties

For workplaces with a risk of fire and explosion, there is now a European standard, DIN EN 16350:2014, which defines the test conditions and minimum requirements for the electrostatic properties of safety gloves:

- The contact resistance must be less than 1.0 × 108 ohms (Rv< 1.0 × 108 Ω).

- Test atmosphere: air temperature of 23 ± 1 °C, relative humidity 25 ± 5 %.

Important! Safety gloves with antistatic characteristics are only effective if the resistance between the wearer and the earth is less than 108 ohms. Our products are tested in accordance with DIN EN 16350:2014 and are suitable for both product and work protection. What should the user look out for?

The old classification in accordance with DIN EN 1149-1:2006 is no longer permitted. The tested surface resistance only gives the charge transfer to the surface of the material and is not sufficient to guarantee effective protection. What can gloves tested in accordance with DIN EN 16350:2014 be used for?

Safety gloves that have been successfully tested in accordance with DIN EN 16350:2014 can be used in workplaces with a risk of fire and explosion (e.g. refineries) and form an essential part in the earthing chain (glove – protective clothing – shoes – ground). In connection with electrostatic properties, the electrostatic discharge ("electrostatic discharge", or "ESD") is frequently considered in the area of product protection. Safety gloves tested in accordance with DIN EN 16350:2014 can be used for all applications of ESD product protection.

DIN EN 60903:2003 Live working – Gloves made from insulating material

DIN EN 60903-compliant safety gloves are category iii PPE. The insulation protection class of the insulating personal protective equipment (PPE) is determined according to the nominal voltage of the plant, with both the maximum permissible nominal AC voltage (AC) and the nominal DC voltage (DC) being calculated.

Labelling of safety gloves

| Insulation protection class | Max. permissible nominal AC voltage (AC) | Max. permissible nominal direct voltage (DC) |

| 00 | 500 volts | 750 volts |

| 0 | 1000 volts | 1500 volts |

| 1 | 7,500 volts | 11,250 volts |

| 2 | 17,000 volts | 25,000 volts |

| 3 | 26,500 volts | 39,750 volts |

| 4 | 36,000 volts | 54,000 volts |

Additional identifier

| Category | Resistant to |

| A | Acids |

| H | Oil |

| Z | Ozone |

| C | Extremely low temperatures |

DIN EN 61482-1-2:2015-08 Live working - Protective clothing against the thermal hazards of an electric arc

Part 1–2: Test methods – Method 2:

Determining the arc protection class of the material and the clothing using a directed test arc (box test)

Hands are at the greatest risk of burns from short circuit electric arcs when working on electrical equipment. Unfortunately, there is no recognised standard for safety gloves in Germany for testing the potential dangers of a short circuit electric arc. Therefore, safety gloves for protection against the thermal discharge of a short circuit electric arc are generally tested in accordance with EN 61482-1-2 and classified accordingly.

| Class | Test current [kA] | Arcing time [ms] | Arc energy [kJ] | Incident energy [kJ/m2] |

| 1 | 4 | 500 | 168 +/- 17 | 146 +/- 28 |

| 2 | 7 | 500 | 320 +/- 22 | 427 +/- 39 |

ISO 18889 Standard for safety gloves for users of crop protection products

The EN 18889 standard consists of three performance levels — GR, G1 and G2. G2 offers the highest level of protection.

GR: Partially coated safety gloves provide protection against dried spray coatings during follow-up work

G1: Fully coated safety gloves for handling ready-to-use crop protection products.

G2: Fully coated safety gloves for use with concentrated crop protection products.

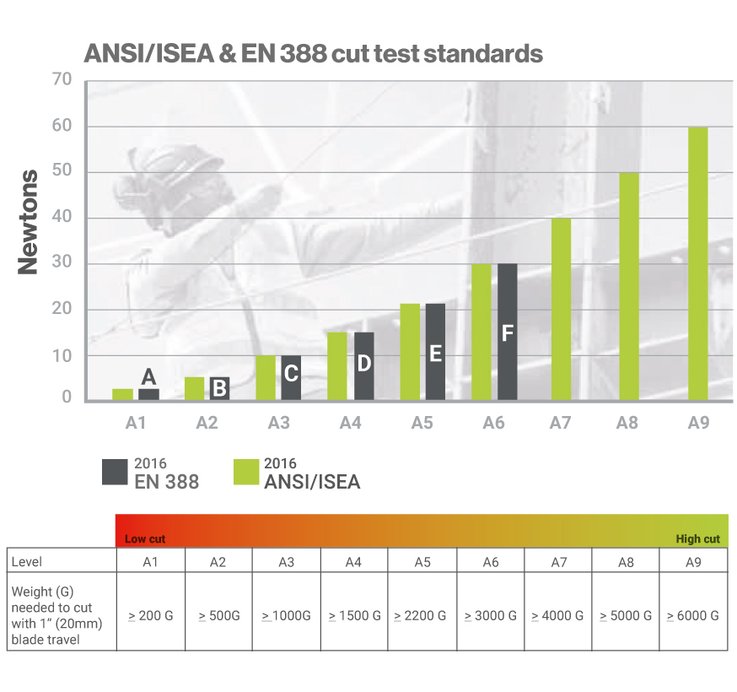

ANSI/ISEA 105-2016 – Cut resistance

Cut resistance levels: The use of the TDM-100 test method is required by both ANSI/ISEA 105 and by EN 388 (for high-cut materials). However, the ANSI/ISEA standard reports results in grams on an A1-A9 scale (200- 6000 grams/2-60 Newtons).

While the A1-A9 scale is comparable to the EN 388 A-F levels which reports up to 30 Newtons (200-3000 grams/2-30 Newtons), ANSI/ISEA extends their scale by three levels to 6000 grams/60 Newtons to report high cut materials more accurately.

ANSI/ISEA 105 – Puncture & Needle Resistance

The ANSI/ISEA 105 Test

In February of 2016, the ANSI/ISEA 105 standard was updated and published to include two puncture standards: Puncture Resistance (other than hypodermic needle) and Hypodermic Needlestick Puncture. Prior to 2015, there was only one puncture test, which did not specify the type of puncture hazard the standard was created for, leaving it open for interpretation. Having both an industrial puncture standard and a hypodermic needle puncture standard allows safety managers to differentiate between what protection they need most, based on more relevant testing and classification.

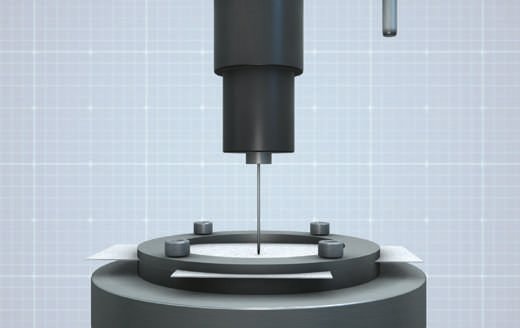

The EN 388 probe is the approved puncture test for ANSI/ISEA 105 and measures the amount of force needed for a blunt probe to pierce through the sample material (taken from palm).

- The blunt probe moves at a 90˚ angle at a speed of 100mm/minute

- Results are reported in Newtons and are given a 1-5 classification rating, with 1 being low resistance and 5 being high resistance

- The test is done 4 times for every palm sample

- The lowest score is reported

The ASTM F2878 is the approved puncture test for ANSI/ISEA 105 and measures the amount of force needed for a 25-gauge hypodermic needle to pierce through the sample material.

- The puncture probe (25-gauge needle) travels at a 90˚ angle into specimen at a vector of 500 millimeters per minute.

- Results are reported in Newtons and are giving a 1-5 classification rating, with 1 being low resistance and 5 being high resistance

- The test is done 12 times for every palm sample

- The average of the 12 results is reported

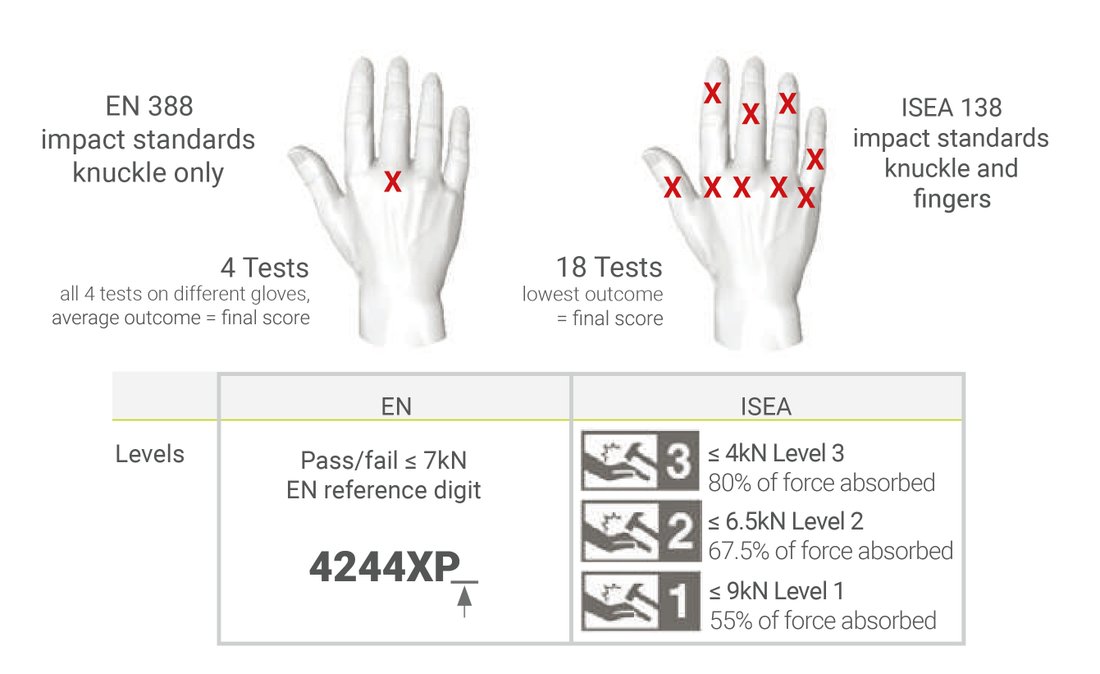

ANSI/ISEA 138 – Impact protection

The ISEA 138 standard establishes the minimum performance, classification, and labeling requirements for gloves that are designed to protect the knuckles and fingers from impacts based on three performance levels:

- Performance Level 1: Results in an average peak transmitted force of less than or equal to 9 kN. - 55% of force absorbed

- Performance Level 2: Results in an average peak transmitted force of less than 6.5 kN. - 67.5% of force absorbed

- Performance Level 3: Results in an average peak transmitted force of less than 4 kN. - 80% of force absorbed

How the test works:

To score gloves into their appropriate level, impact protection testing under ISEA 138 requires consistent, regulated tests on each kind of glove on two areas for impact performance: knuckles and fingers/thumb. On both gloves, knuckles are tested four times and fingers/thumb are tested five times. To start, one pair of gloves is required per test. The gloves are cut in half and the back-of-hand (where the impact protection is located) is placed on an anvil. A striker with a force of 5 Joules is dropped on the required back-of-hand locations, and the amount of force transferred through the glove back-of-hand is recorded with a force gauge that is connected below the anvil and measured in kiloNewtons (kN).

Scoring: The average of eight knuckle tests are compared to the average of the ten finger tests. The highest average of the two is the impact testing score.