Respiratory protection for work in welding

The following includes further information for choosing the right breathing protection for work in welding.

The suggestion made here is only a general recommendation.

For a detailed analysis and selection of the correct mask, please refer to our selection guide:

Correct selection

Please do not hesitate to contact your relevant professional association should you have any queries or questions.

Welding aluminium and stainless steel

Welding of metals such as stainless steel and aluminium releases a combination of hazardous materials in a metal and aluminium oxide smoke. As with all other high-alloy steels, a protection class FFP3 respirator should be worn for adequate protection against these metals.

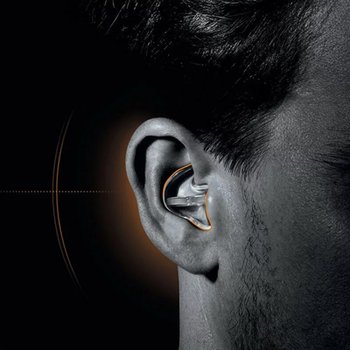

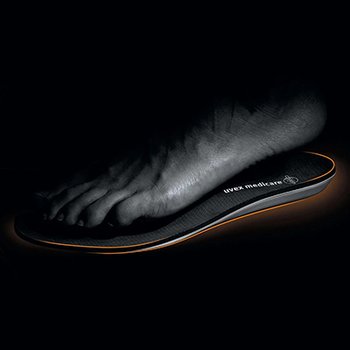

A respirator with carbon should be worn to protect against ozone gas that is released by welding (protection against gases and vapour under occupational exposure limits [OEL]). You can find product suggestions for this purpose below. Please ensure all appropriate and requisite personal protective equipment (PPE) is worn, as offered by uvex.

Brazing

Many different hazardous materials are released during brazing. As with all other high-alloy steels, a protection class FFP3 respirator should be worn for protection when working with metals such as copper and zinc.

A respirator with carbon should be worn to protect against ozone gas that is released by welding (protection against gases and vapour under occupational exposure limits [OEL]). You can find product suggestions for this purpose below. Please ensure all appropriate and requisite personal protective equipment (PPE) is worn, as offered by uvex.

Still haven't found the right one for you?

Find out more about uvex respiratory protection.