Puncture-resistant gloves in everyday work

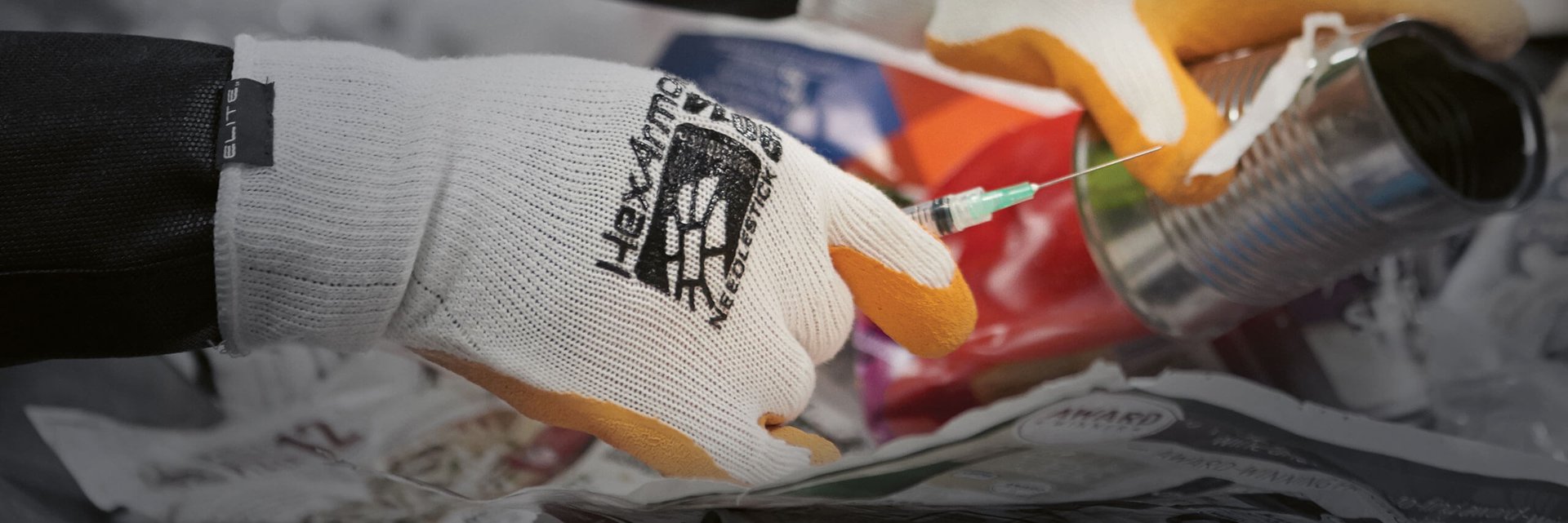

Do you have to deal with sharp objects or hypodermic syringes in your work and are you looking for puncture-resistant work gloves to avoid stab wounds on the back of your hand, the inside of your hand and your fingers? Then you've come to the right place: Our needlestick protection gloves from HexArmor protect your palm in particular when handling sharp components, objects and needles. Since stab and cut injuries can cause serious infections by, for example, hepatitis B and C or HIV, hand protection should not be neglected!

We have summarised the most important information you need when buying puncture-resistant protection gloves.

According to which standards are puncture-resistant gloves certified?

For puncture-resistant gloves in the industrial sector, the version of EN 388 against mechanical risks, which was updated in 2019, applies. This standard also regulates the requirements for abrasion resistance, cut resistance, tear propagation resistance and cut protection.

EN 388:2019 divides the puncture resistance of gloves into five levels of protection. Stab protection testing is about how much force (in Newtons) is required to pierce a specimen material with a rounded probe and at a speed of 100 mm/min.

| Class 0 | 0 to 19.9 Newtons |

| Class 1 | 20 to 59.9 Newtons |

| Class 2 | 60 to 99.9 Newtons |

| Class 3 | 100 to 149.9 Newtons |

| Class 4 | 150 and more Newtons |

The needle-proof gloves for protection against puncture of hypodermic syringes are regulated according to the American standard ANSI/ISEA-105 and are divided into five protection levels according to the test standard ASTM-F2878-10. The test determines how much energy is required to pierce the sample material with a 25 gauge injection needle at a speed of 500 mm/min.

| Level 0 | 0 to 2 Newtons |

| Level 1 | 2 to 4 Newtons |

| Level 2 | 4 to 6 Newtons |

| Level 3 | 6 to 8 Newtons |

| Level 4 | 8 to 10 Newtons |

| Level 5 | over 10 Newtons |

You can find out more details about the test methods of our puncture-resistant gloves in our blog article on standards and guidelines for protective gloves. The level of protection required for your job can be determined from the risk assessment of your workplace.

SuperFabric® – what makes HexArmor'® s puncture-resistant gloves so effective

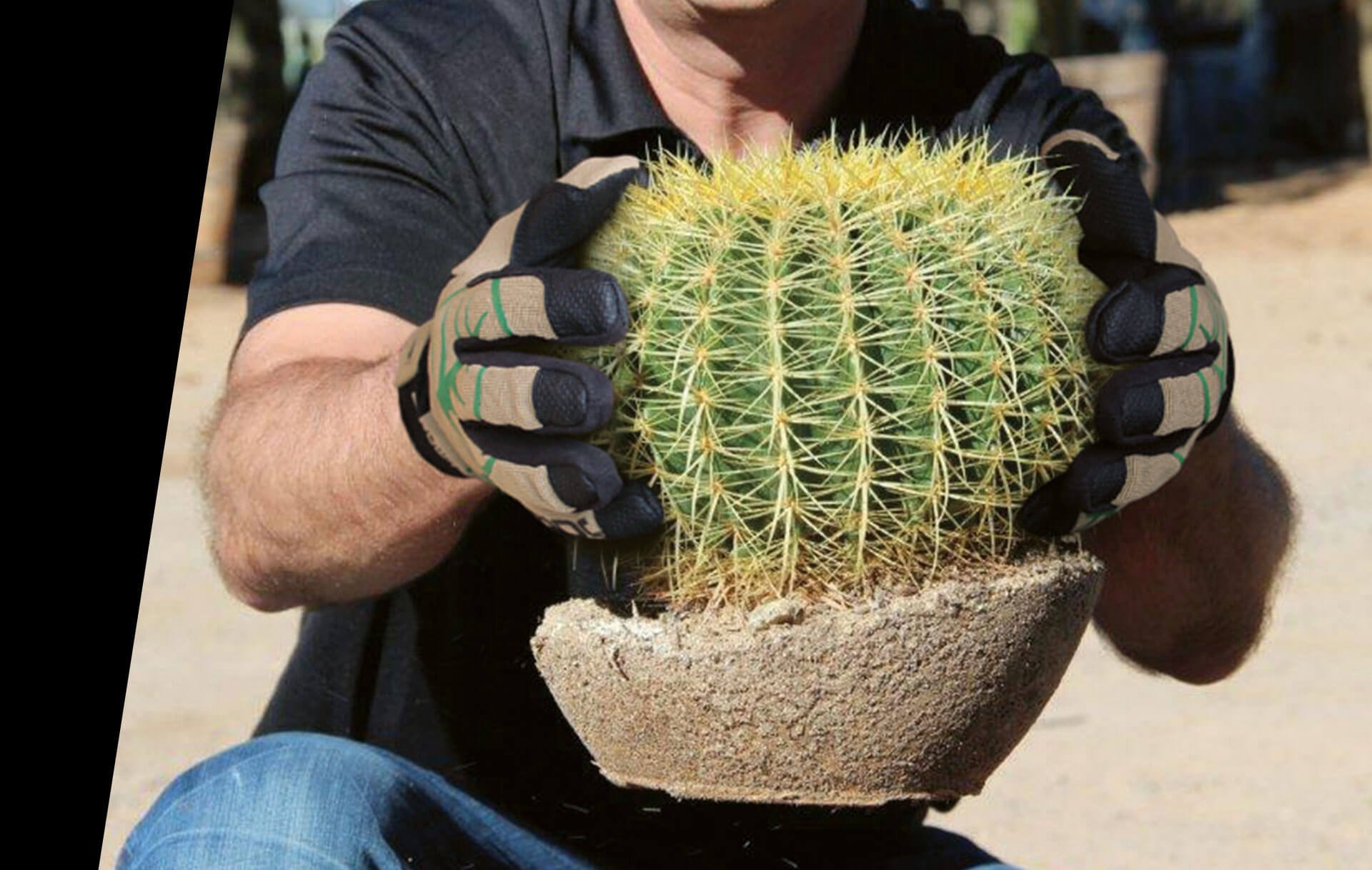

The HexArmor® gloves are characterized by tile-shaped fabric made of SuperFabric® material, which is sewn on top of each other in up to three layers. These protective tiles ensure optimal mobility and adaptability of the robust work gloves to your movements, which ensures optimal wearing comfort!

You can find out what the SuperFabric® technology also means for the protective effect of the cut and puncture-resistant HexArmor® gloves on our website.

In which areas are needlestick protection gloves important?

Puncture-resistant gloves are basically important in any area where sharp objects are used. These include:

For more information on the risks in the recycling industry and HexArmor'® s cut and puncture-resistant gloves, check out our brochure "Needlestick Glove Solutions".

Buy top puncture-resistant gloves at uvex – occupational safety from a professional

Invest in the safety of your employees and equip them with puncture-resistant gloves. This will help you avoid painful stab wounds, dangerous infections and high treatment costs! You can find the right protective glove size in our size chart.

Of course, you can also order chemical protection, cut protection, welding protection, heat protection and cold protection gloves as well as forearm protection gloves from uvex. Visit our range of protective gloves and benefit from the protective properties of our products! Do you need more PPE components? Just take a look at our wide range of products – we will equip you with protective equipment from head to toe!