Manufacturing expertise

We offer personal protective equipment from head to toe, with manufacturing expertise in all areas – and we invite you to judge our expertise.

We place the highest requirements on ourselves

Almost 80 % of our value added is generated in our own plants. These production plants are home to the latest technology, a huge wealth of experience and a passionate desire for product innovation, which is in many ways pioneering.

Strict quality management ensures that we meet the high requirements we have set ourselves and our products – all our plants are certified in accordance with ISO 9001:2008.

Our own product development and a tight network of strategic partners help us to continuously create innovative ideas. Innovations – just as much as existing products – have to prove themselves in our own test laboratories. Only when a product exceeds all the requirements of the relevant safety standard does it earn the right to the uvex name.

Safety helmets

With our advanced expertise in plastics processing, we produce safety helmets and inner shells for bump caps in Germany. High-quality materials and on-going monitoring of all production processes guarantee the highest level of excellence for head protection products.

Head protection covers much more than helmets

Expertise in head protection also means thinking about areas where helmets are not compulsory, but where there is still a risk of head injury. This is why we have developed the uvex u-cap bump cap. The innovative arrangement of the plastic shell elements is inspired by the armadillo – and uniquely combines protection and wearer comfort.

Safety spectacles

At our site in Fürth, we combine everything from safety spectacles and full vision goggles to prescription and laser protection goggles. In this unique competence centre for protective eyewear, we develop and produce, in accordance with strict quality standards, premium coating systems to enhance the properties of our eyewear – and to create high-performance premium products.

laservision – over 30 years of experience in laser protection

With the laservision brand and our product promise "protecting people", we also offer globally standardised cutting-edge technology in laser protection and laser safety spectacles – which we develop ourselves, produce and sell.

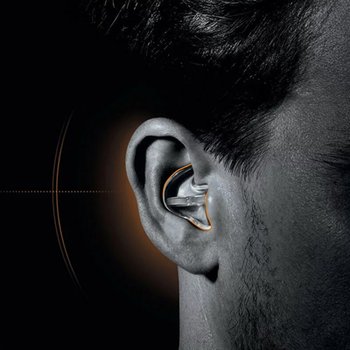

Hearing protection

The uvex range of hearing protection includes earplugs, banded ear defenders, earmuffs (safety headphones) and otoplastics. SwedSafe in Tyringe, Sweden, is our ultra-modern manufacturing plant for hearing protection with its own research and development department all under the same roof. SwedSafe has become one of the leading manufacturers of hearing protection in only a few years since it was established, thanks to its successful network of partnerships with known hearing protection specialists and its collaboration with testing facilities across the world. SwedSafe also sets benchmarks for environmental protection and sustainability. SwedSafe regularly sets the bar just that little bit higher in hearing protection thanks to its innovative drive and its own polyurethane foam that it developed in-house.

Value follows innovation

As a specialist in foam processing, SwedSafe continuously monitors and optimises earplugs and their material composition in terms of cell structures and homogeneity. This achieves optimal reset times and the best possible contact pressure. The many patents relating to earplugs that have been filed are proof of SwedSafe's innovative drive.

uvex safety is synonymous with exceptional industrial health and safety solutions that fulfil the highest demands. These are based on in-depth expertise, the latest technology and uncompromising quality. Almost 80% of the value chain is generated in our own uvex manufacturing plants.

These manufacturing plants bring together the latest technology, innovative power and decades of experience to produce our respirators. Our quality management system ensures compliance with the highest demands and all uvex plants are certified in accordance with ISO 9001:2008. Through strategic partnerships with select manufacturers of high-quality respirators, the uvex safety group has added disposable face masks to its production expertise in the area of personal protective equipment.

Access to the complete value chain enables uvex to use innovative, high-quality materials. The ongoing refinement of manufacturing processes guarantees respirators of the very highest quality.

Face masks

Progressive technology, unwavering commitment to innovation, maximum experience – with this winning combination, we produce ultra-modern respiratory protection with a clear eye for detail. Access to the entire value chain enables us to use and continuously improve high-end materials. With production processes under continuous development and strategic partnerships with selected producers, we achieve a leap forward in quality that our customers rightly expect from the uvex brand.

One-stop protection

As a producer of highly functional face masks and a global leader in industrial eye protection, we consistently co-ordinate our developments processes. For you, this means: at uvex, you get perfectly combinable respiratory and eye protection. No pressing. No slipping. Reliable protection in all conditions.

Occupational and protective clothing

We combine a wide range of textiles under one umbrella brand – from fashionable occupational clothing to customised system solutions via innovative protective clothing: uvex is a design, development and production expert in one location with an integrated system landscape and perfectly co-ordinated processes. With modern materials and plenty of know how, we make sure that in addition to reliable protection there's ample wearer comfort too.

Textile competence centre in Ellefeld

With uvex safety textiles based in Ellefeld, Germany, we cover innovative protective clothing solutions, as well as corporate fashion and individual clothing requests. We have a professional consultancy and development team comprising designers and textile specialists to support you from your initial idea through to delivery of your very own product – all from one source, including safety footwear, protective eyewear and gloves adapted to your corporate identity.

uvex competence center for hand protection in Lüneburg

uvex safety gloves, based in Lüneburg, Germany, is the uvex safety group's competence and technology center for hand protection, with research & development, in-house laboratories, and highly flexible production. This ensures high technological standards in the production of hand protection solutions as well as short distances from the manufacturer to the user.

For 95 years, uvex has remained true to Germany as its production location and is one of the largest manufacturers in the hand protection category still producing in Germany and Europe. In times of global resource shortages and limited transport capacities, this locational advantage is crucial when it comes to the availability and delivery of the products.

At the same time, uvex maintains control of the entire value chain: From the initial idea through research and development to manufacturing with state-of-the-art production processes. A fully integrated development process in Lüneburg includes:

- own yarn/liner manufacturing

- own compounding (blending)

- specially developed moulding and process technology

- innovative coating technology

- development of customer-specifi c solutions

- technical modifications to existing products (e. g. thermal lining)

- individual production (e. g. gloves for disabled people)

State-of-the-art robot-controlled plant technology and strict production controls guarantee that our safety gloves are of first-class quality. Agile product development is carried out by cross-functional teams, with competencies from a wide range of disciplines and expert areas. A sustainable environmental and energy management ensures a resource-saving and CO2-neutral production.

The specialist manufacturer of protective gloves, which are used for example in the automotive, chemical, mechanical engineering and electrical industries, represents the largest protective glove production in Europe with more than 250 employees. uvex safety gloves stands for outstanding quality "made in Germany", sustainable products as well as high innovation.

Innovation and sustainability

One of the main differentiators from our competitors from Asia are the environmentally friendly production processes in Lüneburg.

For example, our production has been 100% solvent-free for more than ten years and has been almost completely supplied with CO2 neutral energy sources since 2016. In our product development, we are looking for ways to significantly reduce the CO2 footprint of future products by selecting the right materials as early as the product design phase. We are also driving forward new production processes for our series production that will further reduce our energy consumption.

Sustainable production

- CO²-neutral manufacture

- Sustainable environmental and energy management (ISO 14001/ISO 50001)

- Solvents and plasticisers not used in production

- Made locally in Germany

Health

- Over-compliance with REACH regulations on eliminating harmful substances

- Ongoing analysis of almost 200 critical substances (uvex harmful substances standard)

- DERMA certified free from allergenic substances

Comfort

- Extremely comfortable thanks to the use of breathable natural and functional fibres

- Optimum tactile feel thanks to an ergonomic fit

- Natural feel against the skin

Social responsibility

- Full implementation of the ILO standard

- Announced and unannounced social audits at partner companies (uvex social standard)

- Social engagement with a focus on disadvantaged children

We know exactly what you want

Our expertise is available for you at all times which forms the basis of our on-site. Risk-hazard analysis service: Our hand protection specialists work with you to determine which safety gloves are best suited to your individual requirements. Seminars, laboratory analyses and online tools round off our service portfolio. Find out more.

Safety footwear

With an ultra-modern shoe factory in Ceva, Italy, we have set ourselves the challenge of manufacturing technically demanding safety footwear at the highest level of quality and production in Europe and with short paths between development, production and delivery. The plant in Italy is able to manufacture safety footwear extremely flexibly with a very wide range of PUR and rubber outsoles. In a progressive technology centre at the company's headquarters in Germany, we work constantly on new pioneering ideas for our customers and develop sophisticated innovations.

Custom-fit safety for all

Our expertise in safety footwear doesn't stop at standard fittings: Individually produced orthopaedic inserts or ready-made safety shoes and boots mean that we can help people with a wide range of foot-related conditions to resume a normal working life.

Individual PPE

Our Occupational Health division has been focusing on individual protective products for eyes, ears and feet for many decades. Basic research and development at Fürth, expert staff and on-going product optimisation are the basis for all our adapted protective products. Our high quality standards are safeguarded by costly certification procedures and stringent controls.

Adapted protection in three areas

- Individual eye protection: everything from corrected computer glasses to high-impact goggles with prescription lenses

- Adapted hearing protection: hearing protection ideal for people and for the noise pollution for both hearing impaired and hearing employees

- Orthopaedic foot protection: certified orthopaedic foot protection as a customised insert or individually adjusted ready-made safety shoe/boot