Sustainability Goals: 4 focus areas

We have set ourselves the goal of comprehensively integrating sustainability into our processes. Our first step was to identify four specific focus areas based on our materiality analysis. Measurable and group-wide targets have been developed for the focus areas with the aim of uniform strategic anchoring. The uvex group relies on scientifically based approaches to create our climate protection targets. The detailed targets are listed under the focus areas.

Ecological transformation

We will cut CO₂ emissions, waste and water usage in order to expand our climate targets.

We are working to cut 42% of the greenhouse gases directly caused by our company by 2030 and reduce the remaining CO2 as much as possible. The aim is for uvex group products, production and production facilities to have as little impact on the environment as possible. Water consumption, waste generation and reject rates are therefore being reduced further. We consistently pursue this path and invest in our products and production processes so that the entire value creation chain can be climate neutral by 2045.

Targets:

- Climate neutrality by 2045 for Scope 1–3

- Development of science-based climate protection targets by 2024 (42% reduction in greenhouse gas emissions for Scope 1 and 2 by 2030 compared with base year 2021 [Science Based Targets Initiative — SBTi])

- 50% reduction in absolute waste generation through prevention, reduction and recycling by 2030 compared with base year 2020/21

- 10% reduction in water consumption by 2030 compared with base year 2020/21

- 10% reduction in hazardous waste by 2030 compared with base year 2020/21

- Reduction in reject rates to below 5% by 2030 compared with base year 2020/21

Circular economy as a driver of innovation

We process materials to use them again and again.

The uvex group processes plastics, metals and textiles for its products. Our goal is to keep these materials in circulation. The uvex group is producing more and more products from recycled and bio-based materials. We are also increasingly focusing on recyclable materials for packaging. Following the circular economy approach, our focus is on the introduction of innovative, circular products that can save raw materials and energy. We involve the entire product life cycle—from development and material use to recycling—and design our products to be recyclable, durable and resource efficient.

Targets:

- Increase in the total proportion of sustainable materials (bio-based and recycled materials) to 20% by 2030 compared with base year 2020/21

- Exclusive use of recycled and recyclable materials for packaging by 2030

- Implementation of circular product solutions (Design for Recycling, Retain Product Ownership, Product Life Extension) by 2026

Social responsibility

Those who take responsibility can inspire others to do the same.

Anyone who wants to act responsibly needs to adopt a stance. This paves new paths and can inspire people around the world. With our sustainable thinking and action, we want to set an example to society. This is why we help children and young people in need worldwide with the help of the Rainer Winter Foundation and are continuously expanding our sustainable commitment within the uvex group. We establish not only safe working standards and fair working conditions along the entire supply chain, but also supplier management that is sustainable, eco-friendly, social and transparent. Our employees are also trained on the topic of sustainability transformation. It takes every single one of us to change our world for the better.

Targets:

- We are committed to achieving a Net Promoter Score (NPS) of >40 by 2026.

- We want our employee retention to be "good" at the very least by 2026.

- Development of sustainable supplier management with a focus on eco-friendliness, social aspects and transparency by 2026.

- 90% of our employees to receive sustainability training by 2025.

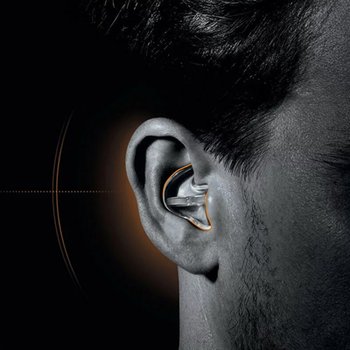

Safeguarding health and the environment

We reduce pollutants through strict controls on our supply chain.

The majority of uvex group products are manufactured in Germany and Europe — on the basis of self-developed standards for particularly harmless and safe materials and production conditions. Systematic supplier controls allow us to minimise the use of potential pollutants. When introducing new processes and products, we pay attention to their safety and possible effects on humans and nature as early as the development phase. Safety you can rely on, made in uvex.

Targets:

- Certification of all European production sites according to ISO 14001 by 2026

- Further development of pollutant management and continuous reduction of defined pollutants

- Monitoring of the number of pollutant findings