Sustainable production

Our innovative products and services for the global market are produced in our own factories, many of which are located in Germany and Europe. As a result, we are responsible for the entire value creation chain — from product conception and development to production and sales. The uvex group can therefore rapidly implement targeted sustainability measures, ensuring the high quality standards of the products.

Sustainability has long been established within our company:

- for uvex, long-term sustainability measures that are widely rolled out are a matter of course.

- 98.4 % of electricity consumption has come from 100 % renewable sources since 2014

- Compensation for CO2 emissions caused by gas combustion has been at 97.3 % of gas consumption since 2016

- "Made in uvex", produced at a European site (max. 1000 km radius from the company headquarters in Fürth)

- Product packaging and outer packaging mainly consist of waste paper, a uniform strategy for sustainable packaging is in development

- Code of Conduct

Our plants

Fürth (Germany)

In Fürth, Bavaria, uvex develops and produces first-class and highly functional safety spectacles, goggles, prescription spectacles and laser protection eyewear. The plant is certified in accordance with ISO 9001:2015 and ISO 50001:2011, and relies on state-of-the-art technology and strategic partnerships to develop future-oriented technologies and products.

- Installation of new energy-efficient flood cells

- Introduction of a new and improved coating system

- Optimised compressed-air system

- Renewal of power distribution in production

Lueneburg (Germany)

The uvex safety group's centre of expertise and technology for hand protection is based in Lueneburg. At a time when resources and transportation capacity are limited, this represents a significant location advantage when it comes to product availability and delivery. uvex safety gloves is therefore one of the largest glove manufacturers still producing in Germany and Europe.

- Investments in new process technologies with a focus on reducing water and energy consumption

- Reduction of paste waste by 50 % through investments in new process technology, mixing skills and consistent work on CIP issues

- Commissioning of the in-house CHP with reduction of energy consumption due to high energy efficiency of >90 %

Ceva (Italy)

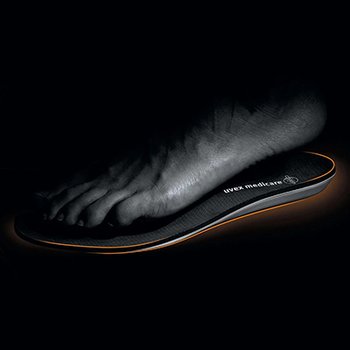

Development expertise, state-of-the-art robot-controlled production systems and optimised process structures to meet the highest ecological standards ensure the first-class and sustainable quality of our safety footwear. The production in Italy, which is one of the most modern production facilities for safety footwear in Europe, ensures efficient, resource-saving production and short travel distances from manufacturer to user.

- Conversion of the occupational safety management system from BS 18001 to ISO 45001

- New, more efficient injection moulding machine

- Conversion to material delivery by tanker trucks

- Conversion of the release agent from solvent based to water based

Tyringe (Sweden)

SwedSafe, part of the uvex group, has a very small carbon footprint. No fossil fuels are used during production and 100% of the electricity required comes from renewable energy sources. To promote biodiversity at the company's premises, natural grasslands were created and populated with flowering plants in order to provide more habitats for insects. SwedSafe is certified in accordance with the ISO 14001 environmental management standard.

- Introduction of environmental management system in accordance with ISO 14001

- Move to a new, modern and larger production site

- Certified in accordance with ISO 45001 and 90001

Rednitzhembach logistics and service centre (Germany)

In operation since 2024, the logistics and service centre sees the uvex group combining modern logistics technology with sustainable building components. The building in Rednitzhembach has received the "Gold" level pre-certification in accordance with the guidelines of the German Sustainable Building Council (DGNB e. V.). Notable highlights include measures to promote biodiversity, a sustainable energy supply with a peak yield of up to 760 kWp of electricity and the operation of a wood-chip heating system, which is supplied by regional suppliers from sustainable forestry.

- 4500 solar panels generate a peak yield of up to 750 kWp of electricity on the roof of the high-bay warehouse

- 6000 m2 of green roof, 59 newly planted deciduous trees and 20 nesting boxes ensure biodiversity

- Picking of goods in 286,720 climate-neutral boxes